How to enable predictive maintenance with magnetostrictive level gauges?

In today's competitive industrial landscape, predictive maintenance has emerged as a crucial strategy for maximizing operational efficiency and minimizing downtime. Among the various technologies enabling this approach, magnetostrictive level gauges stand out as particularly effective solutions for liquid level monitoring applications. These advanced instruments provide the accurate, real-time data necessary for implementing successful predictive maintenance programs across numerous industries including chemical processing, oil and gas, and power generation.

Understanding Magnetostrictive Technology Fundamentals

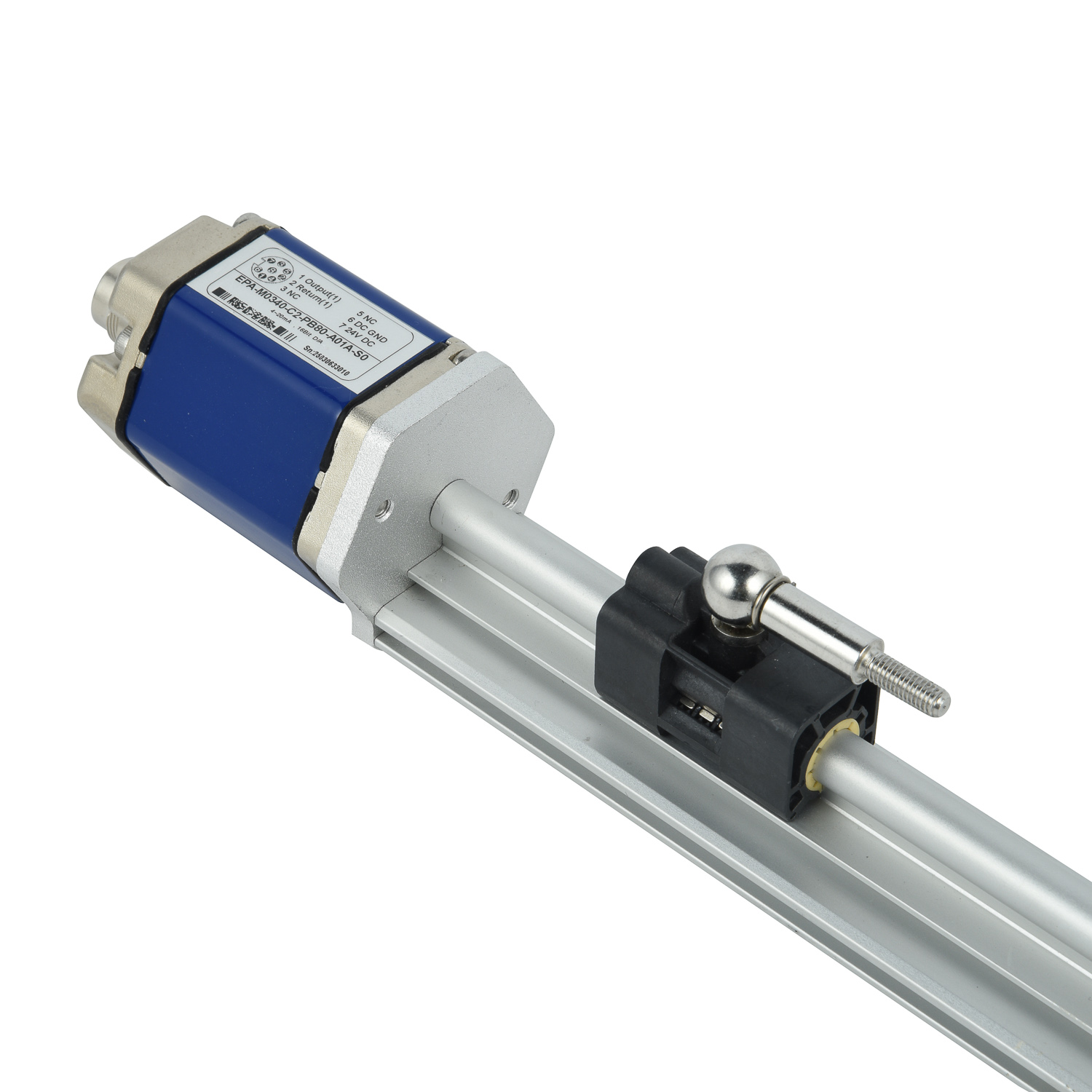

Magnetostrictive level gauges operate on a sophisticated physical principle where a ferromagnetic wire interacts with magnetic fields to deliver precise measurements. The technology utilizes a waveguide wire made of magnetostrictive material that carries current pulses while a permanent magnet floats on the liquid surface. When the current pulse meets the magnetic field from the float, it generates a torsional stress wave that travels back along the wire at ultrasonic speed. By precisely measuring the time delay between pulse transmission and wave detection, these gauges calculate the exact float position with exceptional accuracy, typically within millimeters. This reliable measurement principle forms the foundation for predictive maintenance capabilities.

Data Collection for Maintenance Predictions

The continuous, high-resolution data provided by magnetostrictive level gauges serves as the cornerstone for effective predictive maintenance strategies. These instruments deliver not just level measurements but also temperature readings and diagnostic information through various communication protocols including 4-20mA analog signals, HART, Foundation Fieldbus, and PROFIBUS PA. The rich dataset enables maintenance teams to track performance trends, identify abnormal patterns, and detect early signs of potential failures. By monitoring parameters like signal strength, response time, and measurement stability, operators can anticipate issues before they escalate into costly equipment failures or process disruptions.

Implementing Predictive Maintenance Strategies

Successful implementation of predictive maintenance using magnetostrictive level gauges requires a systematic approach that integrates multiple components. Begin by establishing baseline performance metrics for each gauge during normal operation, then set appropriate thresholds for alerts and alarms. Modern magnetostrictive transmitters feature built-in diagnostic capabilities that monitor their own health while tracking process conditions. Integration with asset management systems allows for automated work order generation when maintenance is predicted to be needed. This proactive approach transforms maintenance from reactive troubleshooting to scheduled, planned activities that minimize production impact.

Analyzing Historical Performance Data

The true power of predictive maintenance emerges when historical data from magnetostrictive level gauges is properly analyzed and utilized. Advanced analytics platforms can process years of level measurement data to identify seasonal patterns, correlate equipment performance with process conditions, and predict remaining useful life of both the gauges and the equipment they monitor. Machine learning algorithms can detect subtle changes in measurement characteristics that indicate developing issues such as float wear, electronics degradation, or process medium changes. This long-term analysis enables continuous improvement of maintenance schedules and strategies.

Cost-Benefit Analysis and ROI Calculation

Implementing predictive maintenance with magnetostrictive level gauges delivers substantial financial benefits that justify the initial investment. The most significant savings come from prevented downtime, reduced emergency repairs, and extended equipment lifespan. Additional advantages include optimized inventory management for spare parts, improved safety through early leak detection, and enhanced regulatory compliance through comprehensive data logging. Organizations typically achieve return on investment within 12-18 months through reduced maintenance costs, improved production efficiency, and elimination of unplanned shutdowns. The continuous operational data also supports better decision-making for capacity planning and process optimization.

Future Trends in Maintenance Technology

The evolution of magnetostrictive level measurement continues to enhance predictive maintenance capabilities through technological advancements. Emerging trends include the integration of IIoT connectivity for cloud-based analytics, wireless communication options for difficult-to-access installations, and enhanced diagnostic features that provide more detailed equipment health information. Smart algorithms are becoming increasingly sophisticated at correlating level data with other process parameters to provide comprehensive asset health monitoring. These developments promise to further improve prediction accuracy and expand the applications where magnetostrictive technology can deliver maintenance optimization benefits.

UpgradingYourLevelMeasurementS

UpgradingYourLevelMeasurementS

Why are magnetostrictive level

Why are magnetostrictive level

ComparingMagnetostrictiveandRa

ComparingMagnetostrictiveandRa

MagnetostrictiveLevelSensorfor

MagnetostrictiveLevelSensorfor