How do magnetostrictive level gauges solve scaling issues of traditional capacitive types?

In industrial process control and inventory management, accurate liquid level measurement is crucial for operational efficiency and safety. Traditional capacitive level sensors have long been employed for these applications, but they face significant challenges when dealing with scaling and buildup on their sensing elements. This persistent issue has driven the need for more robust measurement technologies that can maintain accuracy despite harsh process conditions.

Understanding Capacitive Level Sensor Scaling Problems

Capacitive level sensors operate by measuring the capacitance between a probe and the tank wall, which changes as the liquid level varies. When scale, coating, or material buildup accumulates on the probe surface, it creates a dielectric layer that interferes with the electric field. This buildup causes measurement drift, calibration errors, and eventual complete sensor failure. The problem is particularly acute in applications involving hard water, viscous liquids, or processes where crystallization occurs. Regular cleaning and maintenance become necessary, leading to increased downtime and operational costs.

The Magnetostrictive Measurement Advantage

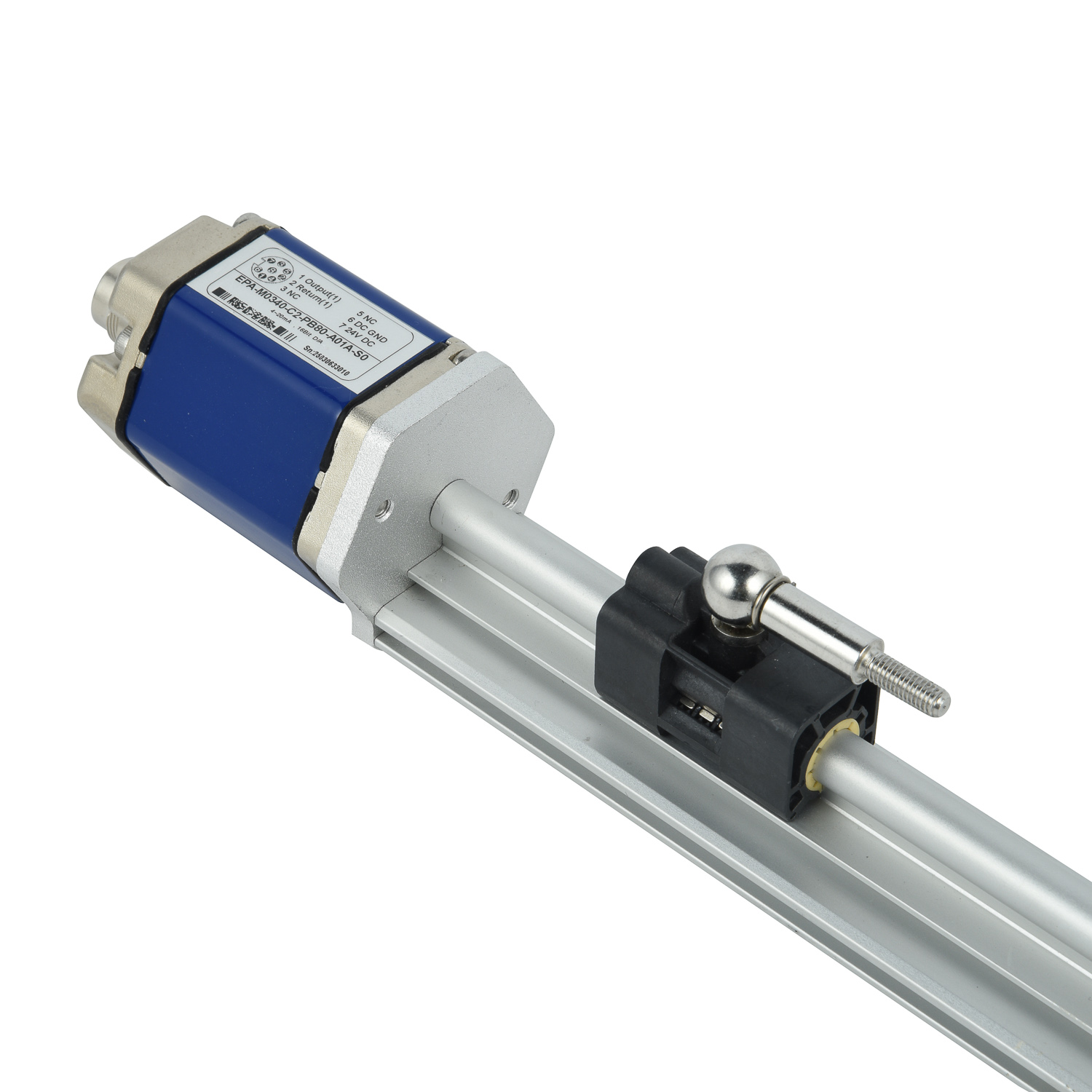

Magnetostrictive level gauges employ a fundamentally different operating principle that inherently resists scaling issues. These devices use a magnetostrictive wire enclosed within a protective tube and a float containing permanent magnets that moves with the liquid level. The system measures the time difference between two magnetic fields - one from the float and another from a current pulse sent through the wire. This time-of-flight measurement remains unaffected by surface buildup on the outer tube, ensuring consistent accuracy regardless of scaling conditions.

Superior Performance in Scaling Environments

The non-contact nature of magnetostrictive measurement provides distinct advantages in scaling applications. Since the float moves along the outside of the protective tube and the sensing wire is completely isolated inside, scale accumulation on the tube exterior doesn't compromise measurement integrity. The robust construction allows for thick-walled tubes that resist corrosion and buildup, while still delivering highly precise level readings. This design eliminates the need for frequent recalibration and reduces maintenance intervals significantly compared to capacitive alternatives.

Application-Specific Solutions for Challenging Media

Magnetostrictive level gauges excel in industries where scaling has traditionally plagued measurement systems. In water treatment plants, they accurately measure chemical levels despite mineral deposits. For food processing applications, they handle viscous products like syrups and dairy without performance degradation. In petroleum and chemical processing, they maintain reliability despite paraffin wax buildup or polymer scaling. The technology's immunity to dielectric constant changes further enhances its superiority over capacitive sensors in these demanding environments.

Cost-Benefit Analysis and Long-Term Reliability

While magnetostrictive level gauges may have a higher initial cost than basic capacitive sensors, their long-term operational benefits far outweigh this premium. Reduced maintenance requirements, extended calibration intervals, and improved measurement reliability translate to significant cost savings over the instrument's lifespan. The elimination of scaling-related downtime and the prevention of costly process errors due to inaccurate level readings make magnetostrictive technology the economically superior choice for applications where scaling has been problematic.

UpgradingYourLevelMeasurementS

UpgradingYourLevelMeasurementS

Why are magnetostrictive level

Why are magnetostrictive level

ComparingMagnetostrictiveandRa

ComparingMagnetostrictiveandRa

MagnetostrictiveLevelSensorfor

MagnetostrictiveLevelSensorfor