What's the future development trend of magnetostrictive displacement sensor technology?

The landscape of industrial sensing is continuously evolving, and magnetostrictive displacement sensor technology stands at the forefront of this transformation. These sensors, renowned for their high accuracy and reliability in measuring linear position, are poised for significant advancements. Understanding their future development trends is crucial for industries relying on precision measurement.

Miniaturization and Enhanced Integration

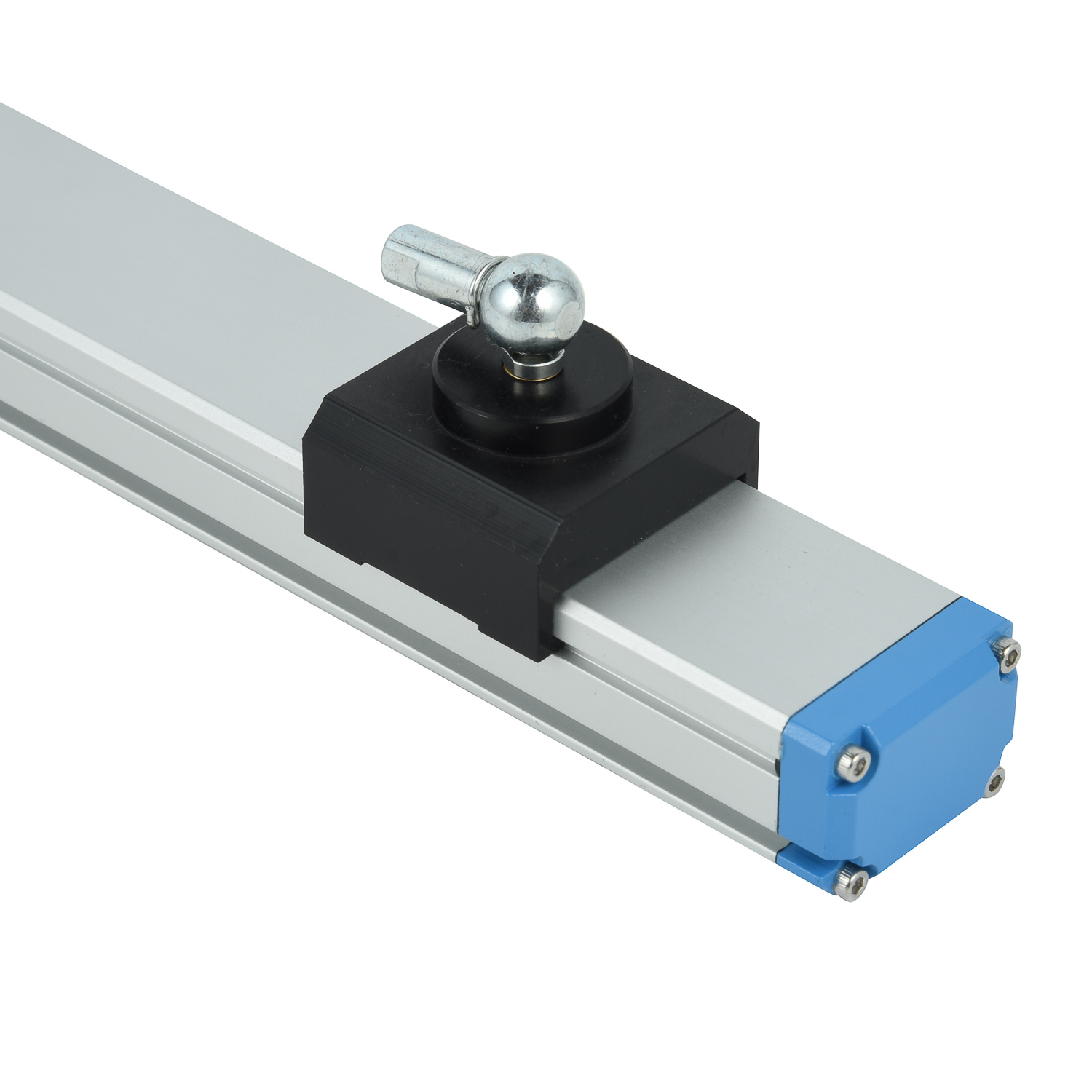

A primary trend shaping the future of magnetostrictive sensors is the relentless drive towards miniaturization. As industrial machinery becomes more compact and complex, the demand for smaller, yet equally powerful, sensors intensifies. Future developments will focus on reducing the physical footprint of the sensor housing and electronics without compromising performance. This miniaturization will be coupled with enhanced integration capabilities, allowing sensors to be seamlessly embedded into hydraulic cylinders, actuators, and other tight-space applications. This trend directly supports the need for more streamlined and efficient machine designs.

Seamless Connectivity for Industry 4.0 and IIoT

The integration of Industry 4.0 principles and the Industrial Internet of Things (IIoT) is a dominant force. Future magnetostrictive sensors will evolve from simple data providers to intelligent nodes within a connected ecosystem. We anticipate built-in IO-Link communication becoming standard, enabling parameter configuration, remote diagnostics, and predictive maintenance data transmission. This connectivity allows for real-time monitoring of system health, reducing unplanned downtime and optimizing operational efficiency. Sensors will not just measure position but also communicate their own status, contributing to smarter, self-aware manufacturing environments.

Breakthroughs in Precision and Resolution

While already known for high accuracy, the quest for even greater precision is unending. Advancements in signal processing algorithms and electronic component design will push the resolution and accuracy of magnetostrictive sensors to new levels. This will enable their use in ultra-precision applications previously dominated by other technologies, such as semiconductor manufacturing and advanced metrology. The ability to detect minute positional changes with extreme repeatability will open doors to new markets and more demanding industrial processes.

Expansion into New and Demanding Applications

As the technology matures and becomes more robust, the application scope for magnetostrictive sensors will expand significantly. We foresee increased adoption in harsh environments, with improvements in housing materials and sealing techniques to withstand extreme temperatures, high pressures, and corrosive media. Furthermore, emerging fields like renewable energy, where precise control of hydraulic pitch systems in wind turbines is critical, will become key growth areas. The versatility and durability of these sensors make them ideal for next-generation industrial challenges.

The Path Towards Smarter, More Adaptive Systems

The ultimate trend is the evolution towards intelligent and adaptive sensing systems. Future magnetostrictive sensors may incorporate embedded intelligence to perform onboard calculations, such as velocity and acceleration derived from position data. This reduces the computational load on the main controller. Additionally, adaptive calibration features could allow sensors to self-adjust for environmental changes, ensuring long-term stability and accuracy. This shift from a passive component to an active, intelligent system element represents the most exciting future development for this robust sensing technology.

UpgradingYourLevelMeasurementS

UpgradingYourLevelMeasurementS

Why are magnetostrictive level

Why are magnetostrictive level

ComparingMagnetostrictiveandRa

ComparingMagnetostrictiveandRa

MagnetostrictiveLevelSensorfor

MagnetostrictiveLevelSensorfor