How to enable adaptive measurement with magnetostrictive technology?

In today's rapidly evolving industrial landscape, the demand for precise and reliable measurement systems has never been greater. Adaptive measurement represents the next frontier in sensing technology, offering dynamic adjustment capabilities that traditional fixed systems cannot match. This intelligent approach allows measurement systems to automatically compensate for environmental changes, wear and tear, and varying operational conditions. Magnetostrictive technology stands at the forefront of this revolution, providing the foundation for truly adaptive measurement solutions that deliver unprecedented accuracy and reliability across numerous applications.

Understanding Magnetostrictive Technology Fundamentals

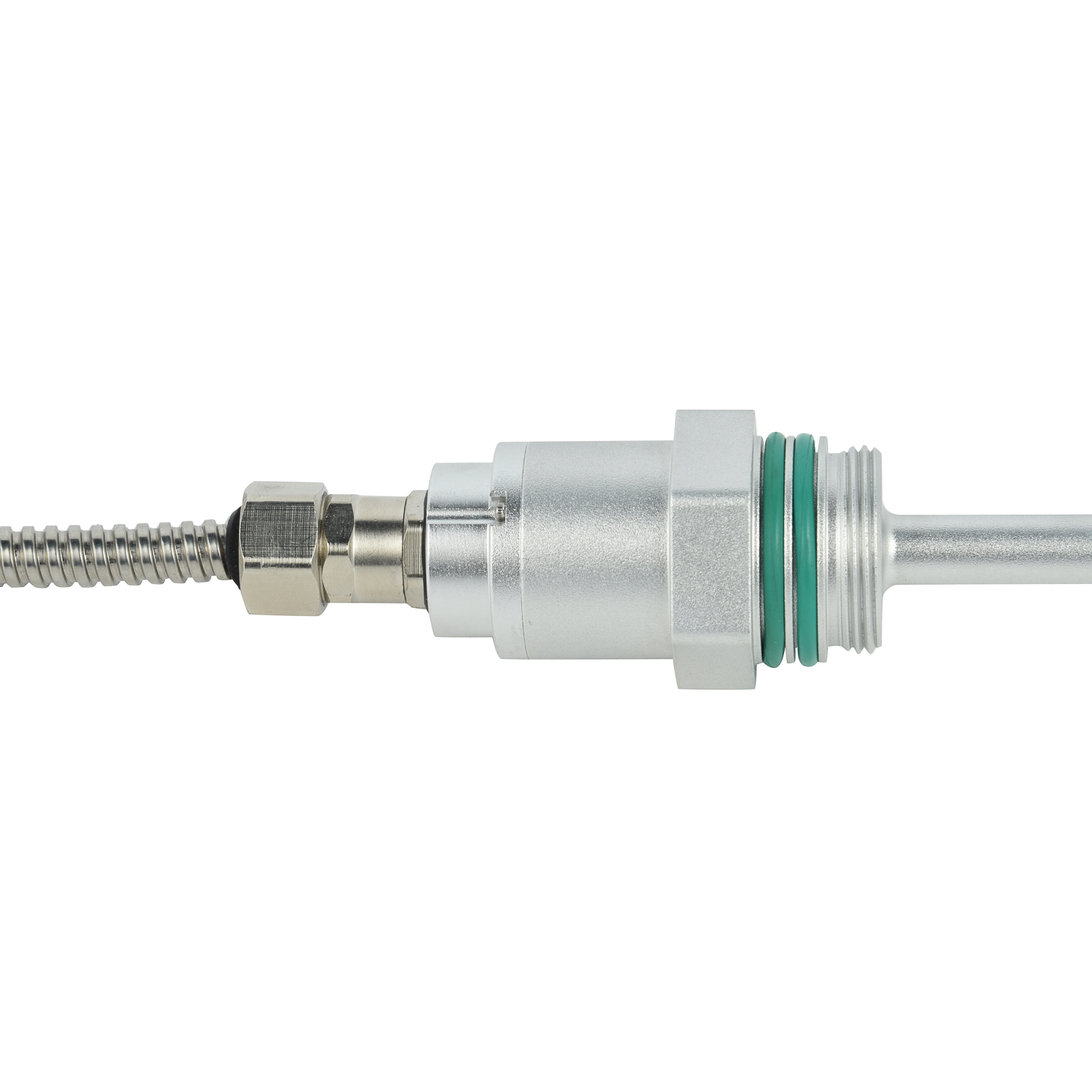

Magnetostrictive technology operates on a fascinating physical principle where certain materials change their shape or dimensions when subjected to a magnetic field. This phenomenon, known as magnetostriction, forms the basis for highly accurate position and displacement measurement systems. The technology utilizes a waveguide made from magnetostrictive material, typically an iron-nickel alloy, which interacts with a magnetic field generated by a position magnet. When a current pulse is sent through the waveguide, it creates a torsional strain wave that travels along the waveguide at a constant speed. The precise timing between the current pulse initiation and the wave's return provides accurate position data, enabling measurements with micron-level precision.

The Core Components of Adaptive Measurement Systems

Implementing adaptive measurement with magnetostrictive technology requires several key components working in harmony. The system typically includes a magnetostrictive sensor, signal conditioning electronics, a microcontroller or processor for data interpretation, and communication interfaces for integration with broader control systems. The sensor itself consists of the magnetostrictive waveguide, a position magnet that moves along the waveguide, and pickup coils that detect the returning torsional wave. Advanced systems incorporate temperature sensors and compensation algorithms to maintain accuracy across varying environmental conditions. These components collectively enable the system to adapt its measurement parameters in real-time, ensuring consistent performance despite changing operational demands.

Implementation Strategies for Adaptive Capabilities

Enabling adaptive measurement requires strategic implementation of both hardware and software components. Begin by selecting magnetostrictive sensors with built-in diagnostic capabilities and temperature compensation features. Integrate these sensors with programmable logic controllers or industrial PCs capable of running adaptive algorithms. The software layer should include machine learning algorithms that analyze measurement patterns and automatically adjust calibration parameters. Implement feedback loops that continuously monitor measurement quality and make real-time adjustments to sampling rates, filtering parameters, and signal thresholds. This approach allows the system to learn from its operating environment and optimize its performance characteristics accordingly.

Calibration and Configuration Best Practices

Proper calibration is crucial for maximizing the adaptive capabilities of magnetostrictive measurement systems. Start by establishing baseline measurements under controlled conditions, using certified reference standards to ensure accuracy. Configure the system's adaptive parameters based on your specific application requirements, considering factors such as measurement range, required resolution, and environmental conditions. Implement multi-point calibration procedures that account for non-linearities across the entire measurement range. Utilize the system's self-diagnostic features to monitor calibration stability over time, and establish automated recalibration triggers based on predefined performance thresholds or environmental changes.

Applications Across Industrial Sectors

Magnetostrictive adaptive measurement systems find applications across diverse industrial sectors. In manufacturing, they enable precise position control in hydraulic cylinders, injection molding machines, and press brakes. The automotive industry utilizes these systems for suspension testing, brake pedal position sensing, and transmission control. In renewable energy, adaptive magnetostrictive sensors monitor blade pitch in wind turbines and gate positions in hydroelectric dams. The technology's ability to maintain accuracy in harsh environments makes it particularly valuable for offshore drilling equipment, mining machinery, and agricultural automation systems where conditions constantly change.

Optimizing Performance Through Advanced Features

Modern magnetostrictive systems offer advanced features that significantly enhance adaptive measurement capabilities. Look for sensors with built-in temperature compensation that automatically adjusts measurements based on thermal expansion coefficients. Consider systems with redundant measurement paths for critical applications where failure is not an option. Implement predictive maintenance algorithms that analyze measurement trends to forecast potential sensor degradation before it affects accuracy. Utilize the technology's inherent immunity to electrical noise and ability to operate without physical contact, which eliminates wear-related inaccuracies and enables truly maintenance-free operation in many applications.

Future Trends and Integration Possibilities

The future of adaptive measurement with magnetostrictive technology points toward increased intelligence and connectivity. Emerging trends include the integration of IoT capabilities for remote monitoring and configuration, artificial intelligence for predictive calibration adjustments, and wireless communication for simplified installation. The convergence of magnetostrictive technology with digital twin concepts enables virtual representation of physical systems, allowing for simulation-based optimization of measurement parameters before implementation. As Industry 4.0 continues to evolve, magnetostrictive adaptive measurement systems will play an increasingly vital role in creating smart, self-optimizing industrial environments that maximize efficiency and reliability while minimizing downtime and maintenance requirements.

UpgradingYourLevelMeasurementS

UpgradingYourLevelMeasurementS

Why are magnetostrictive level

Why are magnetostrictive level

ComparingMagnetostrictiveandRa

ComparingMagnetostrictiveandRa

MagnetostrictiveLevelSensorfor

MagnetostrictiveLevelSensorfor