How to design long-life sensors using magnetostrictive technology?

Understanding Magnetostrictive Principles for Sensor Longevity

Magnetostrictive technology operates on the fundamental principle where certain materials change their shape or dimensions when exposed to a magnetic field. This unique physical phenomenon, known as magnetostriction, provides the foundation for creating exceptionally durable sensors. The key to designing long-life sensors lies in leveraging this inherent material property, which involves minimal moving parts and solid-state operation. Unlike conventional sensing mechanisms that rely on physical contact or delicate components, magnetostrictive sensors generate a signal through the interaction between a magnetic field and a magnetostrictive waveguide. This non-contact sensing method significantly reduces mechanical wear and tear, directly contributing to extended operational lifespan. By deeply understanding the magnetostrictive effect—including the Joule effect and the Villari effect—engineers can optimize sensor designs for sustained performance under demanding conditions.

Selecting Durable Materials for Extended Sensor Life

The choice of materials is paramount in designing magnetostrictive sensors for long-term reliability. High-performance nickel-iron alloys, such as Permendur, are frequently selected for the waveguide due to their strong magnetostrictive coefficient and excellent mechanical stability. The protective sheath material must be chosen based on the application environment; stainless steel (e.g., 316 SS) offers superior corrosion resistance for harsh industrial settings, while Inconel is ideal for high-temperature applications. For the critical permanent magnet, samarium-cobalt (SmCo) or neodymium-iron-boron (NdFeB) magnets are preferred for their resistance to demagnetization and stable magnetic properties over time. The selection process must carefully balance the magnetostrictive sensitivity with factors like tensile strength, fatigue resistance, and corrosion immunity to ensure the sensor can withstand millions of operational cycles without degradation.

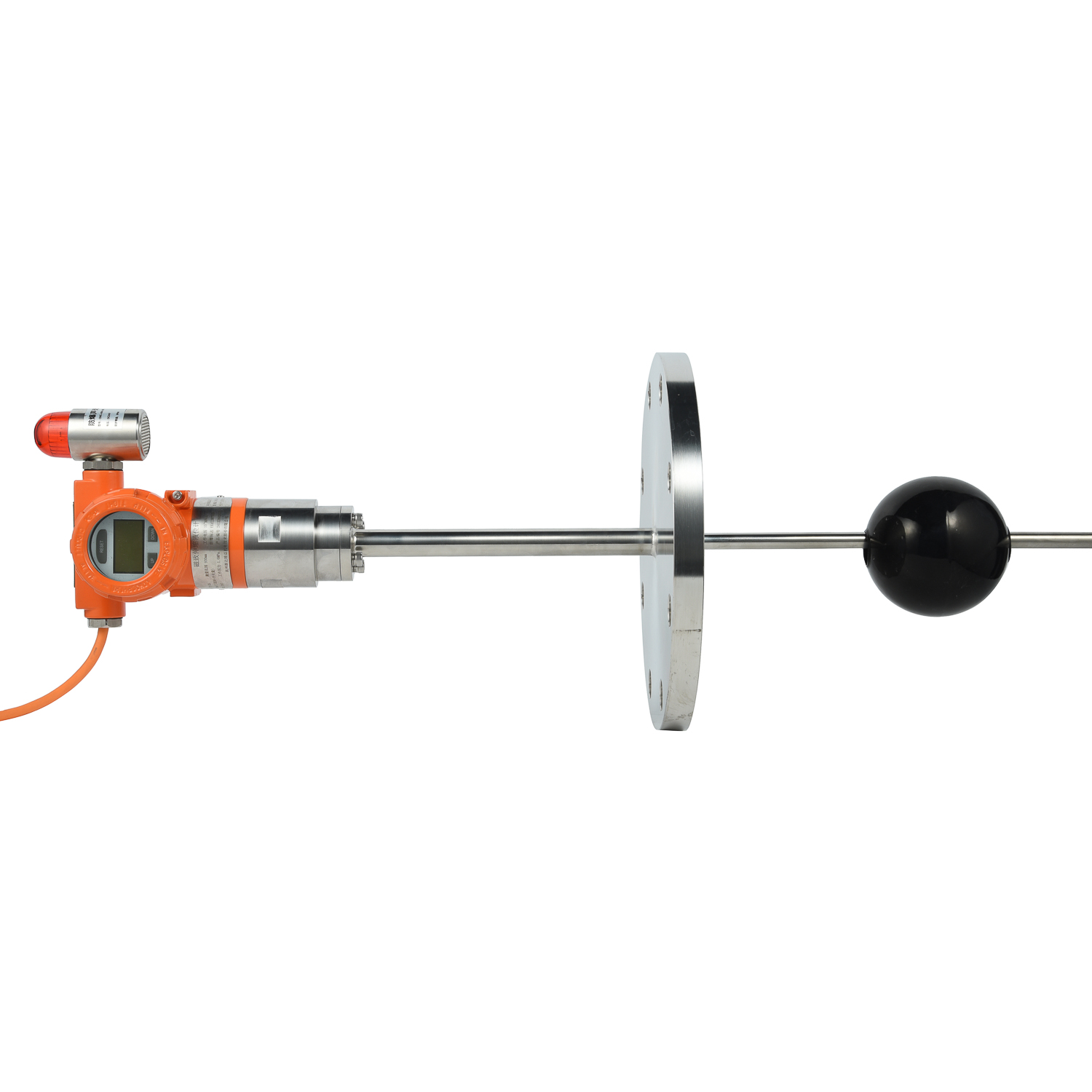

Optimizing Structural Design for Maximum Durability

A robust structural design is crucial for achieving long-life magnetostrictive sensors. The waveguide must be precisely engineered to minimize internal stresses while maintaining the integrity of the torsional wave propagation. This involves careful consideration of diameter, length, and fixation points to prevent harmonic vibrations that could lead to material fatigue. The hermetic sealing at the sensor head is critical for preventing moisture and contaminant ingress, which is a primary cause of premature sensor failure. Advanced designs often incorporate strain relief mechanisms at cable entry points and utilize monolithic construction techniques to eliminate weak joints. By distributing mechanical stresses evenly throughout the sensor body and protecting the internal components from environmental factors, the structural design directly determines the sensor's ability to maintain accuracy over an extended service life in challenging operational conditions.

Implementing Advanced Signal Processing for Reliability

Sophisticated signal processing electronics play a vital role in enhancing the longevity and reliability of magnetostrictive sensors. Modern designs incorporate temperature compensation algorithms that automatically adjust readings based on thermal variations, preventing drift and maintaining accuracy across a wide operating range. Advanced digital signal processors (DSPs) filter out electrical noise and environmental interference that could compromise signal integrity over time. Error-correction protocols and self-diagnostic routines continuously monitor the sensor's health, detecting potential issues before they lead to failure. By implementing these intelligent electronic systems, manufacturers can create sensors that not only provide precise measurements consistently but also predict their own maintenance needs, significantly extending the effective service life and reducing unexpected downtime in critical applications.

Rigorous Testing Protocols for Longevity Validation

Comprehensive testing is essential to validate the long-life performance of magnetostrictive sensor designs. Accelerated life testing subjects prototypes to extreme conditions—including thermal cycling, vibration exposure, and pressure variations—to simulate years of operation within a condensed timeframe. Environmental testing validates performance under specific conditions such as high humidity, salt spray, and explosive atmospheres, ensuring material compatibility and seal integrity. Mechanical endurance tests involve millions of full-stroke movements to verify that the waveguide and damping systems can withstand continuous operation without performance degradation. Electrical testing confirms stability against EMI/RFI interference and power supply fluctuations. These rigorous validation protocols, often exceeding industry standards, provide empirical data that informs design refinements and gives engineers confidence in the sensor's ability to deliver reliable performance throughout its projected lifespan.

UpgradingYourLevelMeasurementS

UpgradingYourLevelMeasurementS

Why are magnetostrictive level

Why are magnetostrictive level

ComparingMagnetostrictiveandRa

ComparingMagnetostrictiveandRa

MagnetostrictiveLevelSensorfor

MagnetostrictiveLevelSensorfor