MagnetostrictiveLevelGaugeforHigh-PressureandHigh-TemperatureApplications

In industrial environments where precision meets extreme conditions, magnetostrictive level gauges stand as the gold standard for reliable liquid level measurement. These sophisticated instruments deliver unparalleled accuracy while withstanding the most demanding operational parameters, making them indispensable across oil and gas, chemical processing, and power generation industries. Their ability to maintain performance under duress separates them from conventional level measurement technologies.

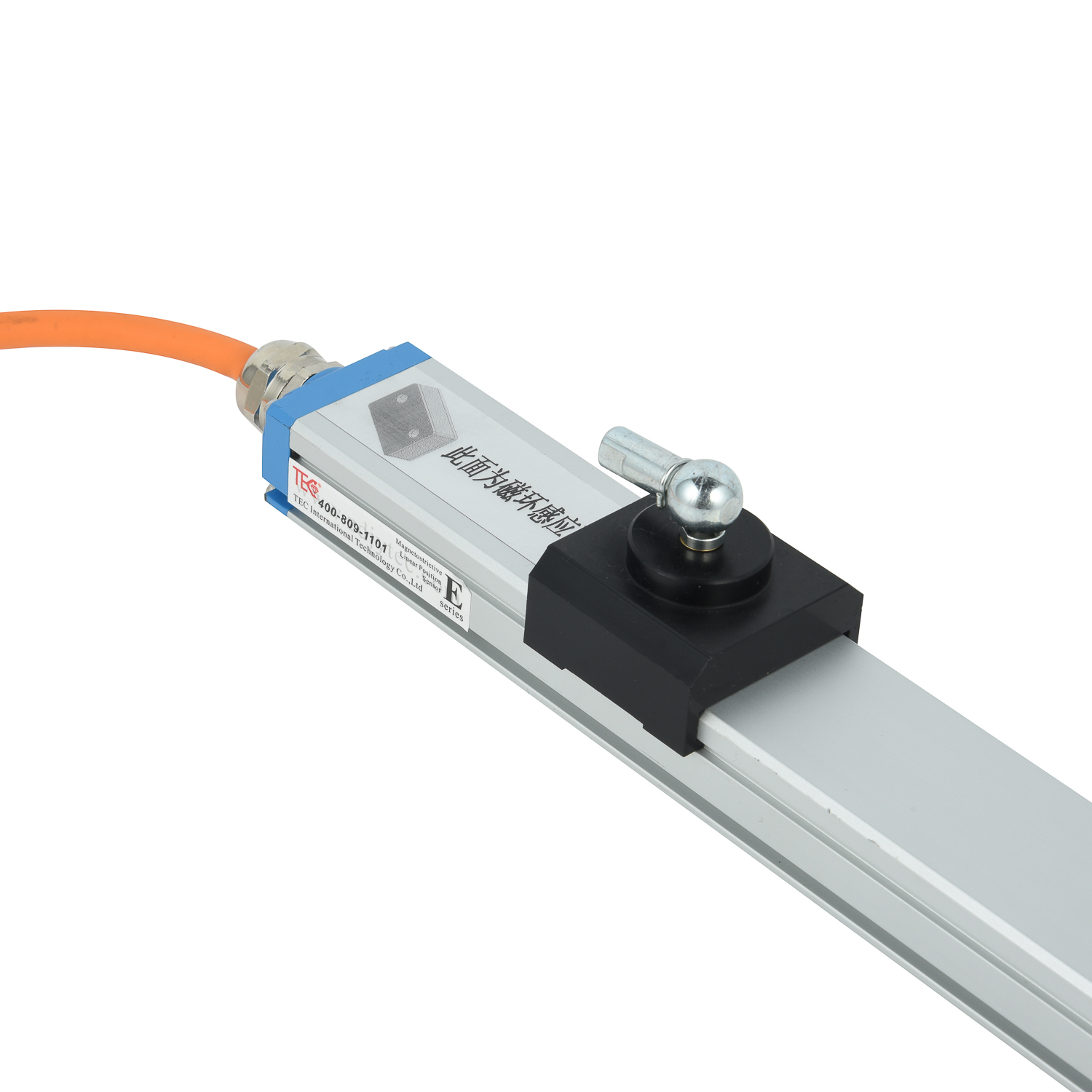

Advanced Operating Principle of Magnetostrictive Technology

At the core of every magnetostrictive level gauge lies a sophisticated physical principle that ensures measurement precision. The technology operates through a magnetostrictive waveguide wire enclosed within a protective tube, where a current pulse generates a circumferential magnetic field along its length. When this field interacts with magnetic fields from float-mounted permanent magnets, torsional stress waves propagate back to the sensing head at ultrasonic speeds. The microprocessor precisely calculates the time differential between pulse transmission and wave return, converting this interval into an exact level reading with resolution up to 0.1% of full scale.

Superior Performance in High-Pressure Environments

Magnetostrictive level gauges demonstrate exceptional resilience in high-pressure applications, consistently performing in systems exceeding 5800 psi. Their hermetically sealed construction and robust housing materials prevent media ingress and structural compromise under extreme pressure cycling. Unlike mechanical float gauges that suffer from compression effects or guided wave radar systems challenged by dense vapor spaces, magnetostrictive sensors maintain their calibration integrity because the measurement principle remains unaffected by pressure-induced density changes. This makes them particularly valuable in hydrocarbon processing, hydraulic accumulators, and supercritical fluid systems where pressure fluctuations would compromise alternative technologies.

Exceptional Stability at Elevated Temperatures

When process temperatures soar beyond conventional measurement capabilities, magnetostrictive level gauges continue delivering reliable data. Engineered with specialized waveguide materials and thermal compensation algorithms, these gauges accurately measure levels in environments ranging from cryogenic conditions to temperatures exceeding 400°C. The technology incorporates temperature-gradient compensation that automatically adjusts for waveguide expansion and contraction, eliminating the measurement drift that plagues lesser technologies. This thermal stability proves critical in refinery fractionating columns, geothermal systems, and high-temperature heat transfer fluid applications where thermal growth would otherwise introduce significant measurement error.

Robust Construction for Demanding Process Conditions

The durability of magnetostrictive level gauges stems from their meticulous engineering and material selection. Constructed from corrosion-resistant alloys like 316L stainless steel, Hastelloy, and titanium, these instruments withstand aggressive media including acids, caustics, and hydrocarbons. Multiple sealing technologies and welded pressure boundaries ensure long-term integrity in hostile environments. The non-contact measurement principle means no mechanical linkage exists between the moving float and sensing element, eliminating wear points that would otherwise limit service life in continuous operation applications. This robust physical construction complements the sophisticated electronics to create a measurement system built for decades of reliable service.

Implementation Advantages in Critical Applications

The implementation benefits of magnetostrictive level technology extend beyond basic measurement functionality. These instruments provide continuous level data with response times under 100 milliseconds, enabling real-time process control unavailable with point-level alternatives. Their digital output capability integrates seamlessly with modern control systems while providing diagnostic data for predictive maintenance programs. With accuracy ratings to 0.05% of full scale and repeatability to 0.001% of span, they deliver the precision necessary for custody transfer operations, inventory management, and safety shutdown systems. The combination of reliability, precision, and durability makes magnetostrictive level gauges the preferred choice for applications where measurement failure is not an option.

UpgradingYourLevelMeasurementS

UpgradingYourLevelMeasurementS

Why are magnetostrictive level

Why are magnetostrictive level

ComparingMagnetostrictiveandRa

ComparingMagnetostrictiveandRa

MagnetostrictiveLevelSensorfor

MagnetostrictiveLevelSensorfor