Real-TimeLevelMonitoringwithMagnetostrictiveSensorTechnology

In today's fast-paced industrial landscape, accurate and reliable level monitoring has become paramount for operational efficiency and safety. Real-time level monitoring represents a significant advancement over traditional measurement methods, providing continuous data that enables proactive decision-making and process optimization. This technology has revolutionized how industries manage their liquid and solid material inventories, offering unprecedented precision in level detection across various applications from chemical processing to water treatment facilities.

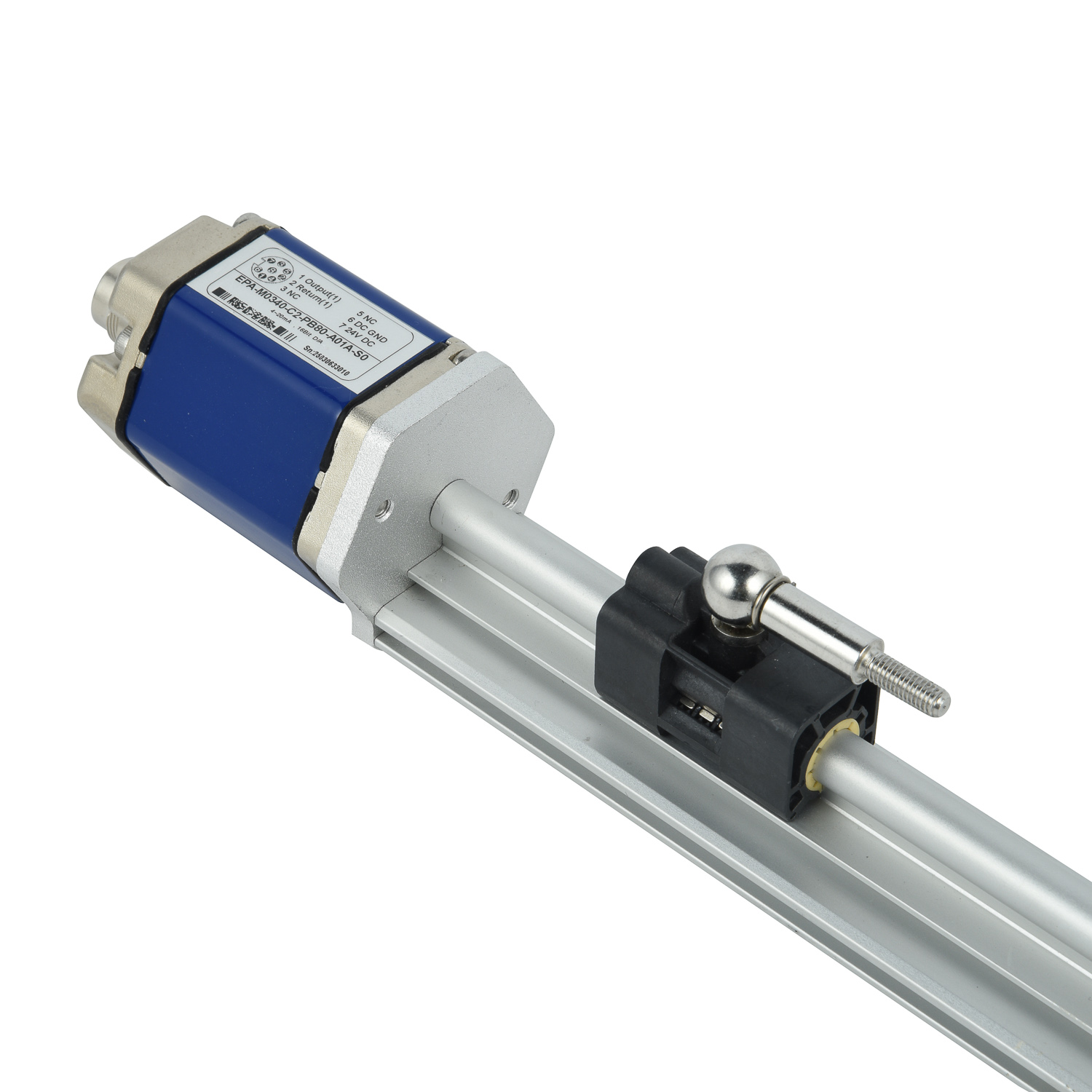

Understanding Magnetostrictive Sensor Technology

Magnetostrictive sensor technology operates on a sophisticated principle that combines magnetic and mechanical phenomena to deliver exceptional measurement accuracy. The core mechanism involves a waveguide wire made of magnetostrictive material that interacts with a permanent magnet housed within a float. When a current pulse is sent through the waveguide, it generates a circumferential magnetic field that interacts with the float's magnetic field, creating a torsional stress wave. This wave travels along the waveguide at ultrasonic speeds, and the time difference between the current pulse initiation and wave detection precisely determines the float position, translating to accurate level measurement.

Key Advantages of Magnetostrictive Level Sensors

The implementation of magnetostrictive sensors for level monitoring brings numerous benefits that outperform conventional measurement technologies. These sensors deliver exceptional accuracy, typically within ±0.05% of full scale, making them ideal for applications requiring precise inventory management. Their non-contact measurement principle ensures minimal wear and extended operational lifespan, while the robust construction allows reliable performance in harsh industrial environments. Additionally, magnetostrictive sensors provide continuous real-time data without moving parts, reducing maintenance requirements and eliminating calibration drift common in mechanical measurement systems.

Industrial Applications and Implementation

Magnetostrictive sensor technology finds extensive application across multiple industries where precise level monitoring is critical. In the oil and gas sector, these sensors accurately measure hydrocarbon levels in storage tanks and processing vessels. Chemical manufacturing plants utilize them for monitoring corrosive and hazardous materials, while power generation facilities rely on them for fuel and water level control. The food and beverage industry benefits from their hygienic design and accuracy in ingredient proportioning. Proper implementation involves careful consideration of factors such as material compatibility, temperature ranges, pressure conditions, and installation requirements to ensure optimal performance.

Integration with Modern Control Systems

The true potential of magnetostrictive sensor technology emerges when integrated with modern industrial control and monitoring systems. These sensors typically feature multiple output options including 4-20mA analog signals, HART protocol, and various digital communication interfaces that seamlessly connect with PLCs, DCS, and SCADA systems. This integration enables comprehensive data logging, remote monitoring capabilities, and automated control functions. Advanced models incorporate self-diagnostic features that alert operators to potential issues before they affect measurement accuracy, thereby enhancing overall system reliability and reducing downtime.

Future Trends and Technological Advancements

The evolution of magnetostrictive sensor technology continues to address emerging industrial needs through innovative enhancements. Current developments focus on improving signal processing algorithms for better noise immunity and measurement stability in challenging applications. The integration of IoT capabilities enables predictive maintenance and cloud-based data analytics, while miniaturization efforts are creating compact sensors for space-constrained applications. Emerging trends also include enhanced safety certifications for hazardous areas, improved materials for extreme temperature operations, and wireless connectivity options that simplify installation and reduce wiring costs in existing facilities.

UpgradingYourLevelMeasurementS

UpgradingYourLevelMeasurementS

Why are magnetostrictive level

Why are magnetostrictive level

ComparingMagnetostrictiveandRa

ComparingMagnetostrictiveandRa

MagnetostrictiveLevelSensorfor

MagnetostrictiveLevelSensorfor