BestMagnetostrictiveLevelGaugeBrandsandManufacturers

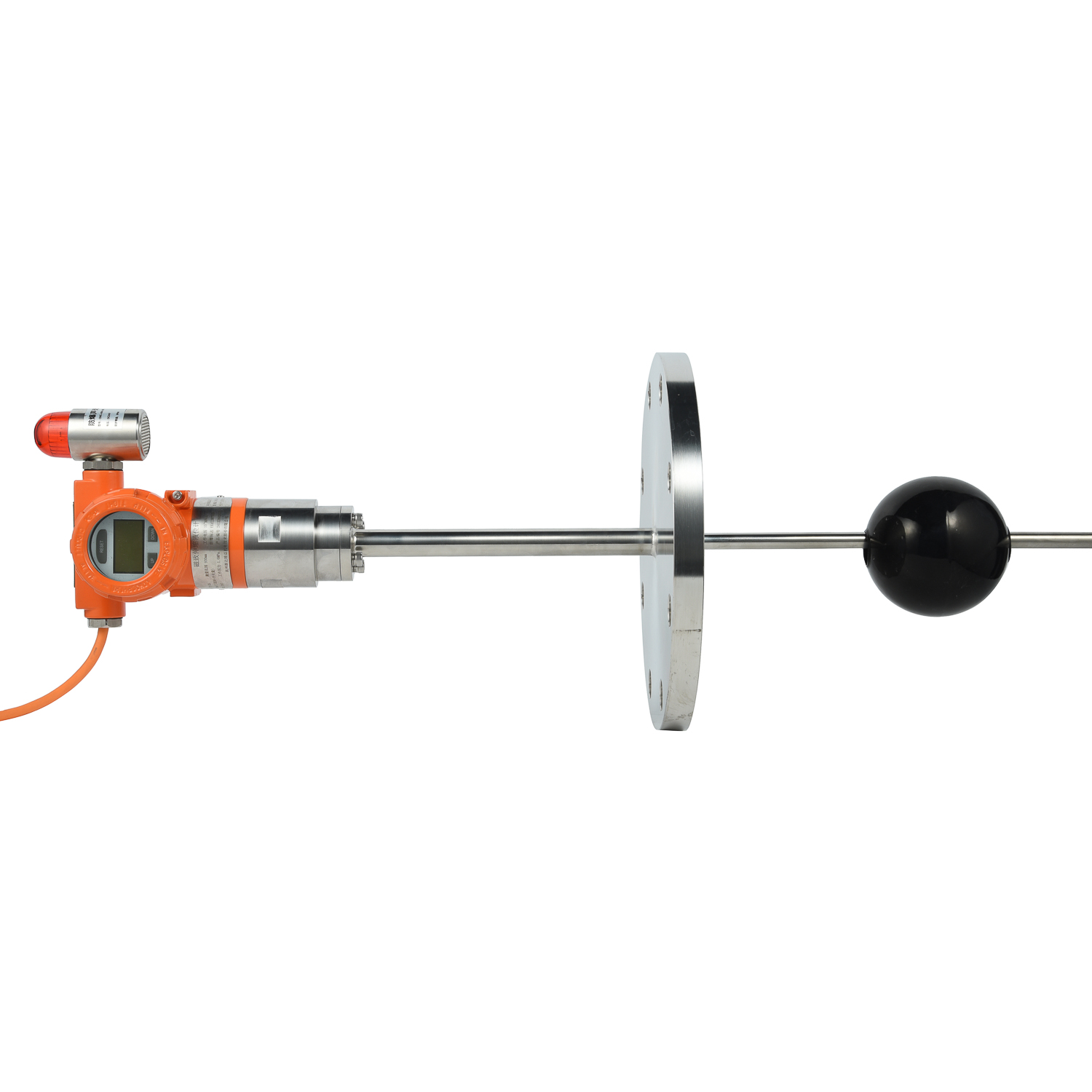

When it comes to achieving unparalleled accuracy in liquid level measurement, magnetostrictive level gauges represent the gold standard for numerous industrial applications. These sophisticated instruments utilize magnetostriction technology to deliver precise, reliable readings for everything from chemical processing to fuel storage tanks. The fundamental principle involves a magnetic field interaction between a waveguide and a float-mounted permanent magnet, generating torsional stress waves that are measured with exceptional precision. This technology outperforms traditional measurement methods with its non-contact operation, minimal maintenance requirements, and immunity to temperature and pressure variations that often compromise alternative technologies.

Leading Magnetostrictive Level Gauge Brands Setting Industry Standards

The landscape of premium magnetostrictive level gauge manufacturers is dominated by several established industry leaders. MTS Sensors stands at the forefront with their Temposonics series, renowned for exceptional reliability and sub-millimeter accuracy across demanding applications. AMETEK's Magnetrol brand maintains a formidable reputation with their E3 Modulevel transmitters, specifically engineered for challenging process conditions. GEMS by Fortive offers robust solutions for hydraulic and lubrication systems, while Siemens SITRANS L series provides seamless integration with industrial automation platforms. These manufacturers consistently push technological boundaries while maintaining rigorous quality control standards that ensure long-term operational stability in critical measurement scenarios.

Key Selection Criteria for Industrial Magnetostrictive Gauges

Choosing the appropriate magnetostrictive level gauge requires careful evaluation of several performance parameters beyond basic brand recognition. Measurement accuracy remains paramount, with high-end models achieving ±0.01% full-scale accuracy for critical applications. Consider the specific gravity range compatibility with your process media, as this directly impacts float selection and measurement reliability. The construction materials must withstand process temperatures ranging from cryogenic conditions to elevated temperatures exceeding 200°C, while also resisting chemical corrosion from aggressive media. Additional considerations include pressure rating compatibility, output signal options (4-20mA, HART, Profibus, Foundation Fieldbus), and safety certifications for hazardous area installations.

Innovative Features in Modern Magnetostrictive Level Instruments

Contemporary magnetostrictive level gauges incorporate sophisticated features that significantly enhance their operational capabilities and user experience. Advanced digital signal processing algorithms now provide exceptional noise immunity and stability, even in electrically noisy industrial environments. Many premium models feature dual-float configurations capable of simultaneously measuring interface level and total level for immiscible liquids. Integrated diagnostics continuously monitor system health, predicting maintenance needs before failures occur. Smart calibration capabilities allow for remote adjustment and configuration through intuitive mobile applications, while modular designs facilitate component replacement without complete system recalibration.

Applications Across Major Industrial Sectors

The implementation of magnetostrictive level technology spans numerous industries where measurement precision directly impacts operational efficiency and safety. In chemical processing plants, these gauges provide critical level data for reactors, separators, and storage vessels handling corrosive substances. The oil and gas sector relies on them for precise inventory management in crude oil tanks, LNG storage, and refinery process vessels. Power generation facilities utilize them for feedwater heater monitoring and turbine lube oil protection systems. Additional applications include pharmaceutical bioreactors, food processing vessels, and marine ballast tank monitoring, demonstrating the technology's remarkable versatility across diverse operational environments.

Comparative Analysis of Top Manufacturer Capabilities

A thorough comparison of leading magnetostrictive level gauge manufacturers reveals distinct competitive advantages across different application segments. MTS Sensors excels in high-performance applications requiring extreme precision and fast response times, particularly in hydraulic and test stand applications. AMETEK Magnetrol demonstrates superior performance in harsh chemical environments with their extensive material compatibility options. Siemens provides unmatched integration capabilities for plants utilizing comprehensive automation systems, while GEMS focuses on cost-effective solutions for OEM applications without compromising reliability. This differentiation enables specifiers to match manufacturer strengths with specific project requirements rather than adopting a one-size-fits-all approach.

Future Trends in Magnetostrictive Level Measurement Technology

The evolution of magnetostrictive level gauge technology continues to advance toward increasingly intelligent and connected instrumentation. Emerging developments include enhanced wireless communication capabilities utilizing Industrial IoT protocols for seamless data integration with plant asset management systems. Manufacturers are developing miniaturized versions for space-constrained applications without sacrificing measurement performance. Advanced diagnostics now incorporate machine learning algorithms to identify subtle performance degradation patterns before they impact measurement accuracy. The integration of additional measurement parameters including density, viscosity, and temperature within single probe configurations represents the next frontier in comprehensive process monitoring solutions.

UpgradingYourLevelMeasurementS

UpgradingYourLevelMeasurementS

Why are magnetostrictive level

Why are magnetostrictive level

ComparingMagnetostrictiveandRa

ComparingMagnetostrictiveandRa

MagnetostrictiveLevelSensorfor

MagnetostrictiveLevelSensorfor