MagnetostrictiveLevelSensorSpecificationsandTechnicalData

Understanding Magnetostrictive Level Sensors

Magnetostrictive level sensors represent the pinnacle of precision measurement technology for liquid level applications. These sophisticated devices operate based on the magnetostrictive effect principle, where a ferromagnetic material changes shape when exposed to a magnetic field. The core mechanism involves a waveguide wire enclosed within a protective tube, with a float containing permanent magnets that moves along the outside of this tube. When an electrical current pulse is sent through the waveguide, it interacts with the magnetic field from the float, generating a torsional stress wave that travels back to the sensor head. The precise time measurement between pulse transmission and wave reception determines the exact float position, translating to accurate level measurement.

Operating Principle and Technology

The fundamental technology behind magnetostrictive sensors combines electromagnetic physics with sophisticated electronic timing. A current pulse generator initiates measurement cycles by sending brief electrical pulses down the waveguide wire. Simultaneously, the magnetic field from the float-mounted permanent magnets creates an interaction point along the waveguide. This interaction produces a mechanical twist in the wire that travels at sonic speed toward the pickup device. The sensor's electronics precisely measure the time difference between the initial current pulse and the returning stress wave, calculating level position with exceptional accuracy. This non-contact measurement method ensures minimal wear and long-term reliability.

Key Performance Specifications

Magnetostrictive level sensors deliver impressive performance metrics that make them ideal for demanding industrial applications. Standard accuracy ratings typically range from ±0.5mm to ±1.0mm, with high-resolution models achieving measurements as precise as ±0.1mm. Repeatability specifications generally fall within ±0.25mm, ensuring consistent performance across multiple measurement cycles. These sensors operate effectively across broad temperature ranges, with standard models functioning from -40°C to +85°C and specialized versions extending to +125°C. Pressure ratings vary by design but commonly withstand operating pressures up to 345 bar (5000 psi), making them suitable for high-pressure tank applications.

Electrical Characteristics and Requirements

The electrical specifications of magnetostrictive sensors ensure compatibility with industrial control systems. Most units operate on 24 VDC power supplies, with variations available for different voltage requirements. Current consumption typically ranges between 15-30 mA during normal operation. Output options include industry-standard 4-20 mA analog signals, RS-485 Modbus communication, and various fieldbus protocols like PROFIBUS and Foundation Fieldbus. Electrical connections commonly feature IP67-rated connectors or conduit entries, providing robust environmental protection. Intrinsic safety certifications allow operation in hazardous areas where explosive atmospheres may be present.

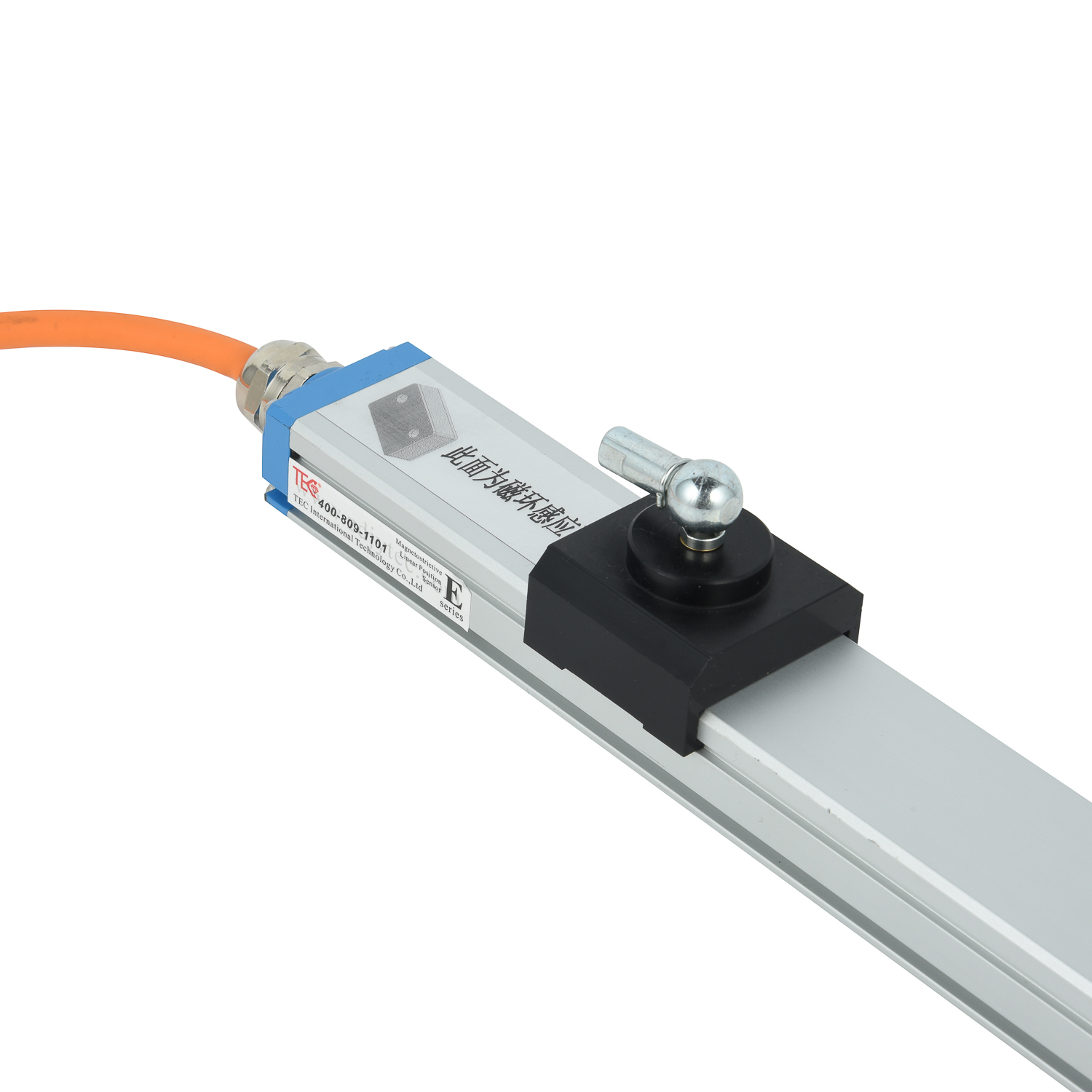

Mechanical Design and Construction

Magnetostrictive sensors feature rugged mechanical designs engineered for industrial environments. The probe material selection includes 304 and 316 stainless steel for corrosive applications, with Hastelloy options available for severely aggressive media. Standard probe diameters range from 9mm to 25mm, with lengths customizable from 0.5 meters to 6 meters. Float designs vary according to specific gravity requirements, with standard models typically rated for specific gravities as low as 0.5. The mounting configurations include threaded, flanged, and hygienic connections compatible with standard industrial tank fittings. All wetted materials comply with industry standards for material compatibility and corrosion resistance.

Installation and Commissioning Guidelines

Proper installation ensures optimal sensor performance and measurement accuracy. Mounting orientation should maintain vertical alignment within ±3 degrees to prevent float binding and measurement errors. The sensor must be positioned to avoid turbulence areas near inlet/outlet nozzles and mechanical agitators. Commissioning procedures involve verifying electrical connections, configuring output parameters, and establishing the measurement reference points. Calibration typically occurs at the factory, with field adjustments available through local interfaces or remote communication protocols. Regular maintenance includes visual inspection for physical damage and verification of measurement accuracy against known reference points.

Application-Specific Considerations

Different industrial applications demand specialized sensor configurations. For interface level measurement between immiscible liquids, specially designed floats detect the boundary between layers based on specific gravity differences. High-temperature applications require specialized float designs and waveguide materials to maintain accuracy under thermal expansion. In sanitary applications, sensors feature polished surfaces, crevice-free designs, and 3-A compliant materials for easy cleaning. Explosion-proof versions carry ATEX, IECEx, or UL certifications for hazardous location installation. Custom engineering solutions address unique challenges like high-vibration environments, extreme pressures, and unusual chemical compatibilities.

UpgradingYourLevelMeasurementS

UpgradingYourLevelMeasurementS

Why are magnetostrictive level

Why are magnetostrictive level

ComparingMagnetostrictiveandRa

ComparingMagnetostrictiveandRa

MagnetostrictiveLevelSensorfor

MagnetostrictiveLevelSensorfor