WhatEveryPlantManagerMustKnowAboutMagnetostrictiveLiquidLevelGauges

Understanding Magnetostrictive Technology

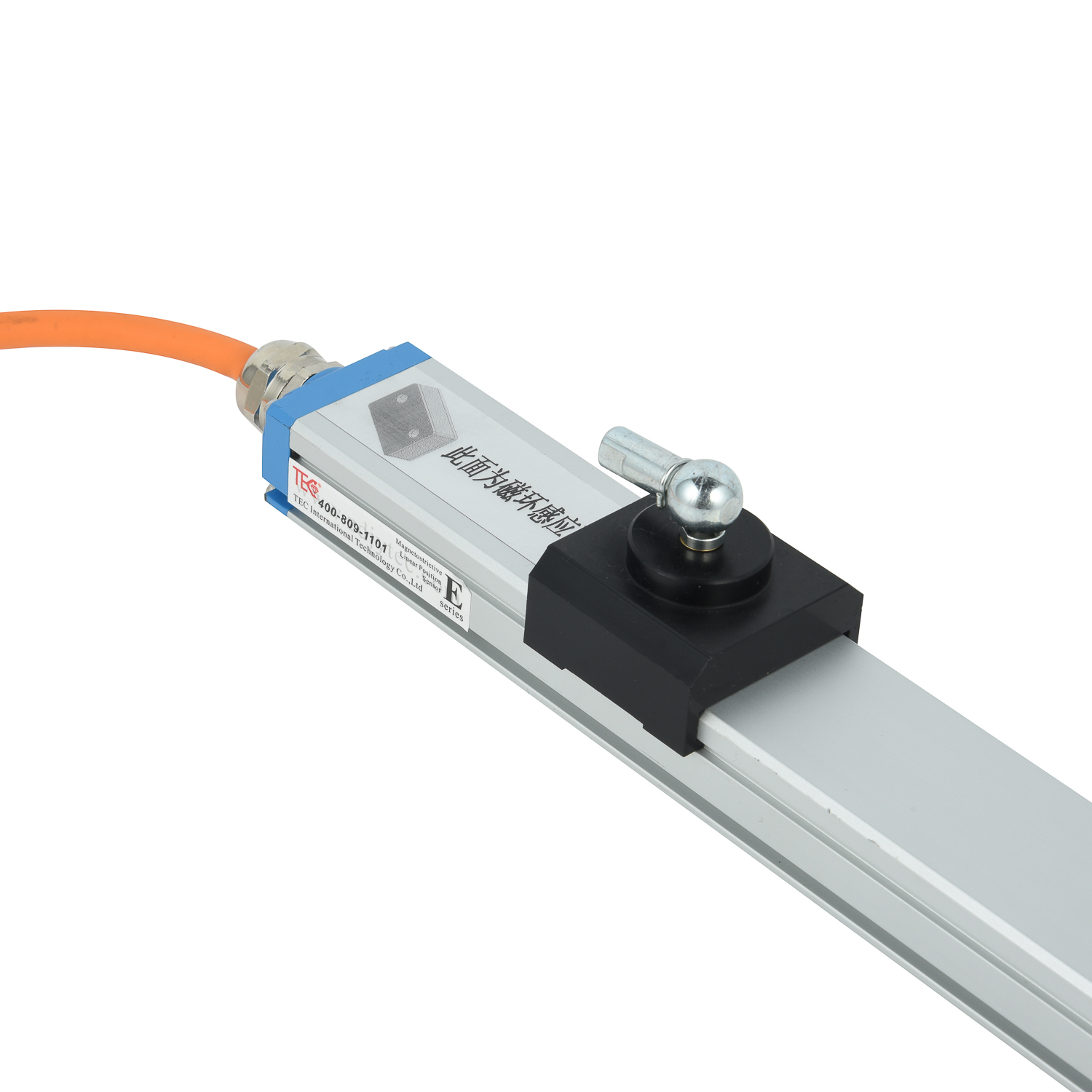

Magnetostrictive liquid level gauges represent the pinnacle of precision measurement in industrial applications. These sophisticated instruments operate on a fundamental physical principle where a ferromagnetic material changes shape when exposed to a magnetic field. In practical terms, the gauge consists of a waveguide wire enclosed within a protective tube. When an electrical current pulse is sent through this waveguide, it interacts with a permanent magnet housed within a float that moves with the liquid level. This interaction creates a torsional stress wave that travels back along the waveguide at a constant velocity. By precisely measuring the time between the current pulse initiation and the return wave detection, the system calculates the exact position of the float - and consequently, the liquid level - with remarkable accuracy.

Key Components and Working Mechanism

The operational excellence of magnetostrictive level gauges stems from their meticulously engineered components. The system primarily comprises three critical elements: the float containing permanent magnets, the waveguide responsible for signal transmission, and the sophisticated electronics module. The float, designed for specific gravity compatibility with the measured liquid, moves freely along the waveguide assembly. When the current pulse travels through the waveguide, it generates a circumferential magnetic field around it. The permanent magnet in the float interacts with this field, creating the characteristic torsional wave. The electronics module not only initiates the current pulse but also measures the precise time interval and converts it into a digital level reading. This entire process occurs within milliseconds, providing real-time level data crucial for process control and inventory management.

Unmatched Accuracy and Reliability Benefits

Plant managers consistently choose magnetostostrictive gauges for their exceptional measurement precision, typically achieving ±0.5mm accuracy or better. This level of precision far surpasses traditional measurement technologies and remains consistent across varying process conditions. The non-contact measurement principle ensures minimal wear and tear, resulting in extended service life and reduced maintenance requirements. Unlike mechanical floats that can stick or bind, magnetostrictive gauges maintain reliable operation even in challenging applications involving viscous liquids, foaming surfaces, or turbulent conditions. The technology's immunity to temperature fluctuations, pressure variations, and specific gravity changes makes it exceptionally reliable for critical process applications where measurement integrity directly impacts product quality and operational safety.

Critical Selection Criteria for Industrial Applications

Selecting the appropriate magnetostrictive level gauge requires careful consideration of multiple application-specific factors. Process temperature ranges dictate the choice of materials and electronics specifications, while pressure ratings determine the required structural integrity. Chemical compatibility remains paramount - the wetted materials must resist corrosion from process media. The specific gravity of the measured liquid directly influences float selection and buoyancy calculations. For hazardous areas, appropriate explosion-proof certifications become mandatory. Modern gauges offer various output options including 4-20mA analog signals, HART protocol, Foundation Fieldbus, or Profibus PA communications. The mounting configuration - whether top-mounted, side-mounted, or customized - must align with tank design and accessibility requirements for optimal performance and maintenance convenience.

Installation Best Practices and Calibration Procedures

Proper installation forms the foundation for optimal gauge performance and longevity. The mounting position must avoid areas of potential turbulence, such as near inlet nozzles or agitators, to ensure stable float operation. Adequate clearance for float movement and future maintenance access proves essential during installation planning. Alignment verification prevents binding and ensures smooth float travel along the entire measurement range. Initial calibration establishes the baseline for accurate measurements, with most modern units featuring intuitive push-button calibration or software-assisted configuration. Regular verification against manual measurements or tank strapping data maintains measurement integrity over time. Implementing proper grounding and signal isolation prevents electrical interference that could compromise reading accuracy in industrial environments.

Maintenance Protocols and Troubleshooting Guidelines

While magnetostrictive gauges require minimal maintenance, establishing proactive maintenance protocols significantly enhances operational reliability. Regular visual inspections should verify float freedom and check for physical damage. Electronic module diagnostics typically include self-test capabilities that monitor system health and signal integrity. Common issues like float coating in viscous applications may require periodic cleaning, while electronics problems often trace to power supply issues or signal wiring faults. Most manufacturers provide comprehensive diagnostic tools that interface with gauge electronics to identify specific component failures. Maintaining proper documentation of maintenance activities and performance trends enables predictive maintenance planning and reduces unexpected downtime. Staff training on basic troubleshooting procedures ensures rapid response to operational anomalies.

Cost-Benefit Analysis and ROI Considerations

The initial investment in magnetostrictive level gauges often exceeds traditional measurement technologies, but the comprehensive cost-benefit analysis reveals significant long-term advantages. Reduced maintenance requirements lower labor costs and inventory expenses for replacement parts. Enhanced measurement accuracy minimizes product giveaway and improves inventory management precision. The technology's reliability directly decreases production losses from measurement-related shutdowns or quality deviations. Modern gauges integrate seamlessly with control systems, enabling automated inventory management and reducing manual measurement labor. Many plants achieve full return on investment within 12-18 months through improved process efficiency, reduced product loss, and decreased maintenance expenditures. The technology's scalability allows phased implementation across multiple vessels, distributing capital investment while building operational experience.

Future Trends and Technological Advancements

The evolution of magnetostrictive level measurement continues with emerging technologies enhancing functionality and integration capabilities. Wireless communication options now enable installation in remote or difficult-to-access locations without costly wiring infrastructure. Advanced diagnostics provide predictive maintenance alerts and performance trending data. Integration with IIoT platforms facilitates data analytics for optimization and remote monitoring. Manufacturers are developing specialized floats for challenging applications including interface level measurement and extreme temperature operations. The convergence of precision measurement with digital communication technologies creates opportunities for enhanced process optimization and automated inventory management systems. These advancements position magnetostrictive technology as a cornerstone of digital transformation initiatives in process manufacturing facilities worldwide.

UpgradingYourLevelMeasurementS

UpgradingYourLevelMeasurementS

Why are magnetostrictive level

Why are magnetostrictive level

ComparingMagnetostrictiveandRa

ComparingMagnetostrictiveandRa

MagnetostrictiveLevelSensorfor

MagnetostrictiveLevelSensorfor