TheShockingAccuracyofMagnetostrictiveLiquidLevelGaugesRevealed

In the world of industrial process control, precision measurement isn't just a luxury—it's an absolute necessity. Among the various technologies available for liquid level monitoring, magnetostrictive liquid level gauges have emerged as a remarkably accurate solution that continues to surprise engineers and plant operators alike. These sophisticated instruments deliver precision that often exceeds expectations, providing reliable data critical for everything from inventory management to process optimization.

The Fundamental Science Behind Magnetostrictive Technology

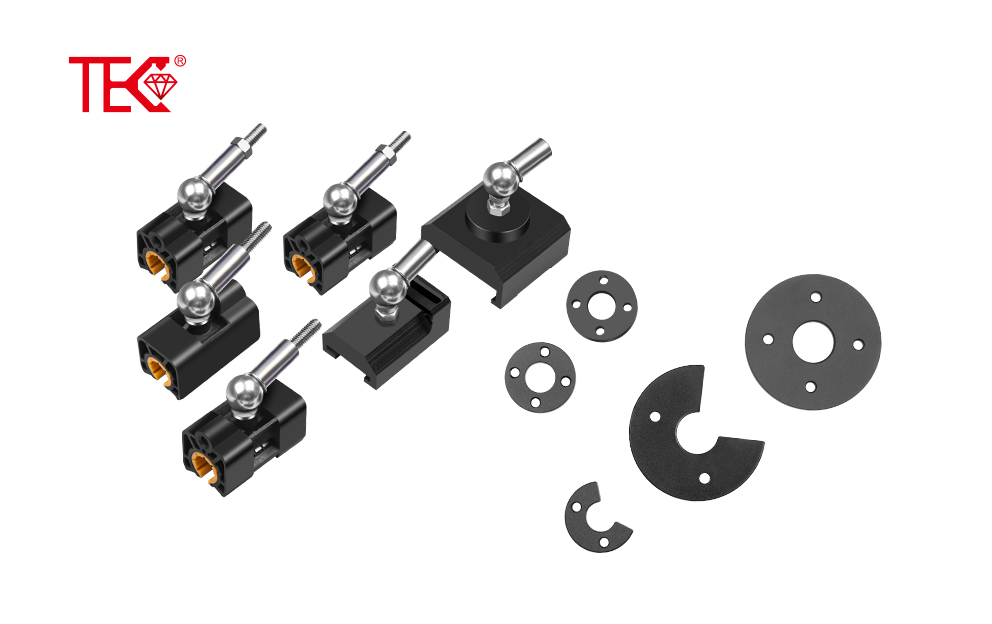

At the heart of every magnetostrictive level gauge lies a fascinating physical principle that enables its exceptional accuracy. These gauges operate based on the magnetostrictive effect, where certain materials change their shape or dimensions when exposed to a magnetic field. The system consists of a waveguide wire surrounded by a float containing permanent magnets. When a current pulse is sent through the waveguide, it interacts with the magnetic field from the float, creating a torsional wave that travels back to the sensor head at a precise velocity. By measuring the time delay between the initial pulse and the returning wave, the gauge calculates the exact position of the float with astonishing precision.

Unmatched Accuracy Specifications That Will Astonish You

What truly sets magnetostrictive gauges apart is their incredible measurement precision, typically achieving accuracy levels within ±0.5mm or even better in some advanced models. This level of accuracy remains consistent across various liquid types, temperatures, and pressure conditions, making these gauges significantly more reliable than traditional float-type or ultrasonic sensors. The non-contact measurement principle eliminates mechanical wear issues that plague other technologies, ensuring the accuracy remains stable throughout the instrument's operational lifespan. This remarkable precision makes magnetostrictive technology ideal for applications where minute level changes can significantly impact process outcomes or inventory calculations.

Superior Performance in Challenging Industrial Environments

Beyond their fundamental accuracy, magnetostrictive liquid level gauges demonstrate exceptional performance stability under demanding industrial conditions. Unlike capacitive sensors that can drift with changing dielectric constants or ultrasonic sensors affected by vapor space conditions, magnetostrictive technology maintains its calibration through temperature fluctuations, pressure variations, and changing liquid properties. The technology proves particularly valuable in applications involving interface level detection between two immiscible liquids, where it can simultaneously track both levels with precision that often surprises operators accustomed to less capable measurement technologies.

Advanced Features That Enhance Measurement Reliability

Modern magnetostrictive gauges incorporate sophisticated features that further boost their measurement reliability and accuracy. Many models include temperature compensation algorithms that automatically adjust readings based on thermal expansion characteristics. Advanced signal processing filters out noise and interference that could compromise measurement integrity. Some systems even incorporate multiple floats for interface level detection or redundant sensing elements for critical applications. These technological enhancements work together to deliver measurement consistency that frequently exceeds operational requirements, making magnetostrictive gauges the preferred choice for applications where measurement uncertainty is not an option.

Cost-Effective Precision for Diverse Industrial Applications

While the technology might seem sophisticated, magnetostrictive liquid level gauges offer surprisingly cost-effective solutions for various industries. Their long-term reliability reduces maintenance costs and minimizes process downtime, while their accuracy prevents product loss through improved inventory control. From chemical processing and petroleum refining to pharmaceutical manufacturing and food processing, these gauges deliver value that extends far beyond their initial purchase price. The technology has proven particularly beneficial in custody transfer applications where measurement accuracy directly impacts financial transactions, often paying for itself through improved measurement certainty.

Future Developments in Magnetostrictive Level Measurement

The evolution of magnetostrictive technology continues to push the boundaries of what's possible in liquid level measurement. Recent advancements include wireless connectivity for easier integration into industrial IoT systems, enhanced diagnostic capabilities for predictive maintenance, and improved materials that extend operational life in corrosive environments. Researchers are developing even more compact designs for space-constrained applications while maintaining the exceptional accuracy that defines this technology. As industries increasingly prioritize data accuracy and reliability, magnetostrictive level gauges are poised to remain at the forefront of precision measurement solutions, continuing to deliver the shocking accuracy that has become their hallmark.

UpgradingYourLevelMeasurementS

UpgradingYourLevelMeasurementS

Why are magnetostrictive level

Why are magnetostrictive level

ComparingMagnetostrictiveandRa

ComparingMagnetostrictiveandRa

MagnetostrictiveLevelSensorfor

MagnetostrictiveLevelSensorfor