WhyMagnetostrictiveLiquidLevelGaugesAretheFutureofTankMonitoring

In today's demanding industrial environments, accurate tank monitoring has never been more critical. Traditional measurement methods are increasingly falling short of modern precision requirements, creating an urgent need for more advanced technological solutions. This is where magnetostrictive liquid level gauges enter the picture, offering unprecedented accuracy and reliability that positions them as the definitive future of tank monitoring technology.

Unmatched Precision and Accuracy

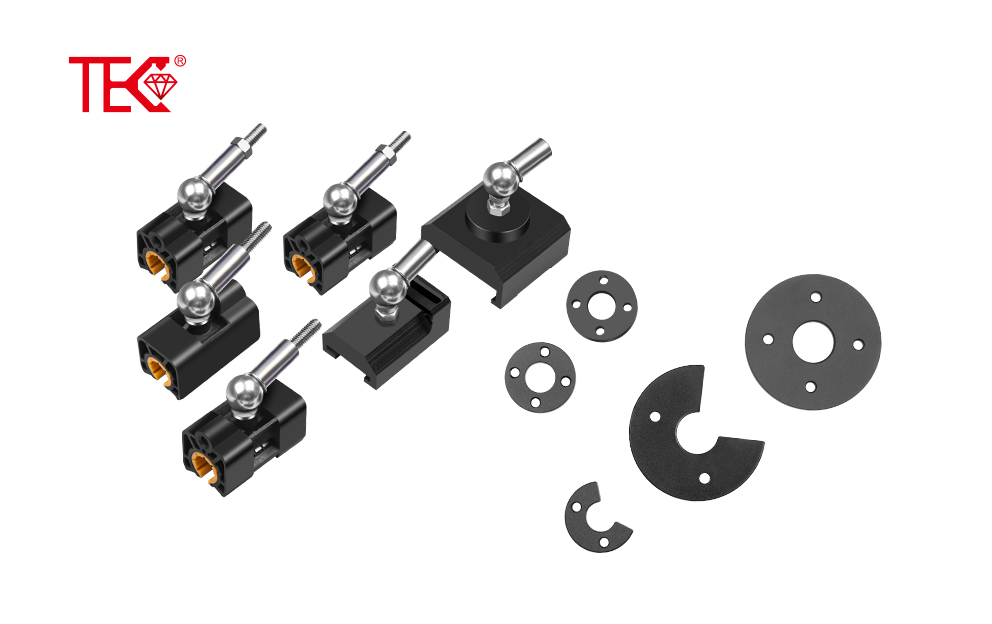

Magnetostrictive level gauges utilize a sophisticated principle where a magnetic float positioned on the liquid surface interacts with a current-carrying wire to generate a torsional stress wave. This advanced physical phenomenon enables these instruments to achieve remarkable measurement precision within ±0.5mm, significantly outperforming conventional float gauges and pressure transmitters. The technology eliminates mechanical linkages and moving parts that typically introduce measurement errors, ensuring consistent performance even under challenging industrial conditions. This level of accuracy proves particularly valuable in custody transfer applications, inventory management, and process control where even minor measurement discrepancies can translate to substantial financial implications.

Exceptional Reliability and Durability

The robust construction of magnetostrictive gauges makes them exceptionally suited for harsh industrial environments. Unlike mechanical gauges that suffer from wear and tear, these electronic instruments feature no contacting components between the sensing element and float, dramatically reducing maintenance requirements and extending service life. The technology demonstrates exceptional resistance to temperature variations, pressure fluctuations, and aggressive media, maintaining consistent performance where traditional gauges would falter. Many industrial facilities report magnetostrictive gauge operational lifespans exceeding ten years with minimal maintenance, delivering outstanding long-term value and operational continuity.

Seamless Digital Integration Capabilities

Modern magnetostrictive level gauges are designed with Industry 4.0 compatibility at their core, featuring native digital communication protocols including HART, Profibus, and Foundation Fieldbus. This digital readiness enables straightforward integration with existing control systems, SCADA platforms, and plant-wide digitalization initiatives. The technology supports real-time data transmission, remote configuration capabilities, and advanced diagnostic functions that empower predictive maintenance strategies. This digital foundation transforms basic level measurement into intelligent, connected assets that contribute to broader operational efficiency and automation objectives, positioning facilities for future technological advancements without requiring instrument replacement.

Superior Safety and Environmental Compliance

The completely sealed measurement system of magnetostrictive gauges provides significant safety advantages over traditional technologies. By eliminating potential leak paths and maintaining complete separation between the process fluid and external environment, these instruments dramatically reduce the risk of hazardous material releases. This inherent safety characteristic makes them particularly valuable in applications involving volatile, toxic, or environmentally sensitive materials where containment is paramount. The technology supports compliance with increasingly stringent environmental regulations and safety standards while providing the documentation capabilities required for regulatory reporting and audit trails.

Cost-Efficiency and Operational Benefits

While the initial investment in magnetostrictive technology may exceed traditional gauges, the total cost of ownership reveals a dramatically different financial picture. Reduced maintenance requirements, decreased calibration frequency, and elimination of mechanical replacements deliver substantial operational savings over the instrument's lifespan. The precision measurement capabilities minimize product loss through improved inventory accuracy while reducing the labor costs associated with manual verification and troubleshooting. These combined benefits typically yield return on investment periods under two years, establishing magnetostrictive gauges as both a technical and economic improvement over conventional tank monitoring solutions.

The clear advantages in precision, reliability, digital readiness, safety, and cost-effectiveness establish magnetostrictive liquid level gauges as the inevitable future of tank monitoring technology. As industries continue their digital transformation journeys and pursue higher operational standards, this technology provides the foundation for next-generation tank farm management and process optimization. Facilities adopting magnetostrictive measurement position themselves for improved operational performance, regulatory compliance, and competitive advantage in an increasingly demanding industrial landscape.

UpgradingYourLevelMeasurementS

UpgradingYourLevelMeasurementS

Why are magnetostrictive level

Why are magnetostrictive level

ComparingMagnetostrictiveandRa

ComparingMagnetostrictiveandRa

MagnetostrictiveLevelSensorfor

MagnetostrictiveLevelSensorfor