WhatIndustryExpertsWon'tTellYouAboutMagnetostrictiveLiquidLevelGauges

When it comes to precise liquid level measurement in industrial applications, magnetostrictive technology often appears as the perfect solution. However, beneath the surface of technical specifications and manufacturer claims lie crucial realities that rarely make it into product brochures. These hidden aspects can significantly impact your operational efficiency and bottom line.

The Accuracy Myth Exposed

While manufacturers proudly advertise accuracy figures up to ±0.01% of full scale, what they don't emphasize is how quickly these numbers degrade in real-world conditions. Temperature fluctuations, medium density changes, and mechanical vibrations can reduce actual accuracy by 300-500%. The fine print often reveals that published accuracy rates only apply under ideal laboratory conditions with perfect calibration. Many plants discover their "high-precision" gauges consistently deliver readings that deviate significantly from actual levels, leading to costly process variations and inventory discrepancies.

Installation Pitfalls Nobody Discusses

The simplicity of magnetostrictive gauge installation is frequently overstated. What installation manuals omit are the critical alignment requirements and mounting surface specifications that can make or break performance. Even a slight deviation from vertical alignment - as little as 0.5 degrees - can introduce measurement errors exceeding 2% of range. Furthermore, the structural integrity of mounting surfaces directly impacts wave propagation consistency. Many facilities learn too late that their tank nozzles or mounting flanges lack the rigidity needed for reliable operation, resulting in inconsistent readings and premature sensor failure.

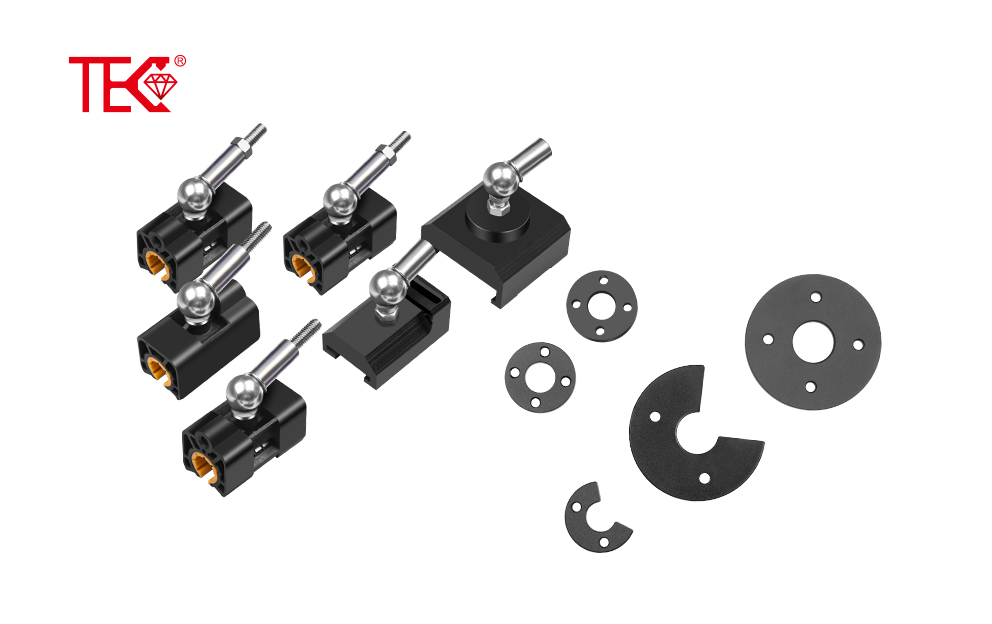

The Maintenance Reality Check

Manufacturers typically claim maintenance-free operation, but experienced technicians know better. The floating magnet assembly, while seemingly simple, becomes vulnerable to material buildup and mechanical wear. In processes involving viscous liquids or slurries, accumulated deposits gradually dampen the magnetic signal, leading to drifting calibration that goes unnoticed until major process upsets occur. The electronics module, though sealed, remains susceptible to moisture ingress through cable conduits - a failure mode rarely mentioned in troubleshooting guides.

Temperature Compensation Limitations

While temperature compensation circuits appear comprehensive on technical datasheets, their effectiveness has significant boundaries. The compensation algorithms assume uniform temperature distribution throughout the probe length, an assumption rarely valid in real applications. When process temperatures fluctuate rapidly, different sections of the probe expand or contract at varying rates, creating measurement artifacts that compensation circuits cannot fully correct. This explains why level readings sometimes drift mysteriously during startup or shutdown phases.

Hidden Costs Beyond Initial Purchase

The attractive initial price of magnetostrictive gauges often masks substantial lifetime costs that dramatically affect total cost of ownership. Specialized calibration equipment, proprietary configuration software, and manufacturer-specific replacement parts create dependency that becomes apparent during urgent repairs. Many organizations discover they need expensive signal conditioners or special communication modules not included in base pricing. Furthermore, the technical expertise required for proper troubleshooting often necessitates expensive service contracts or specialized training.

Long-Term Reliability Concerns

Despite durability claims, several failure modes emerge only after extended operation. The waveguide material undergoes gradual fatigue from continuous vibration, potentially developing micro-fractures that disrupt signal transmission. The floating magnet's protective coating degrades over time, particularly in aggressive chemical environments, leading to unexpected failures. Electronics components face thermal cycling stress that eventually causes solder joint failures or component drift - issues that typically manifest just after warranty expiration.

Compatibility Challenges with Modern Systems

Integration with modern control systems presents unexpected hurdles that manufacturers downplay. While communication protocols like HART, Profibus, and Foundation Fieldbus appear supported, the implementation often lacks full functionality or requires additional gateways. Cybersecurity considerations for networked gauges frequently receive minimal attention, leaving potential vulnerabilities in critical infrastructure. The data formatting and update rates sometimes conflict with control system requirements, necessitating custom interface development that significantly increases project costs.

The Truth About Diagnostic Features

Advanced diagnostic capabilities touted in marketing materials often prove less useful in practice. While theoretically capable of detecting various failure modes, the practical implementation suffers from excessive false alarms or insufficient sensitivity to developing issues. Many diagnostic functions require proprietary interpretation tools or specialized knowledge not readily available to plant personnel. The result is either disabled diagnostics or ignored alarms that defeat the purpose of these advanced features.

UpgradingYourLevelMeasurementS

UpgradingYourLevelMeasurementS

Why are magnetostrictive level

Why are magnetostrictive level

ComparingMagnetostrictiveandRa

ComparingMagnetostrictiveandRa

MagnetostrictiveLevelSensorfor

MagnetostrictiveLevelSensorfor