TheShockingWayMagnetostrictiveLiquidLevelGaugesPreventDisasters

In industrial environments where hazardous liquids are stored and processed, the margin for error is virtually nonexistent. A single miscalculation in liquid level can cascade into catastrophic events including chemical spills, toxic leaks, or even devastating explosions. Traditional measurement methods often fall short in providing the real-time, high-precision data required to maintain safe operational parameters. This is where advanced sensor technology steps in, offering a robust defense against potential disasters. The implementation of magnetostrictive liquid level gauges represents a fundamental shift in how industries approach safety and operational integrity.

The Critical Role of High-Precision Monitoring in Hazardous Environments

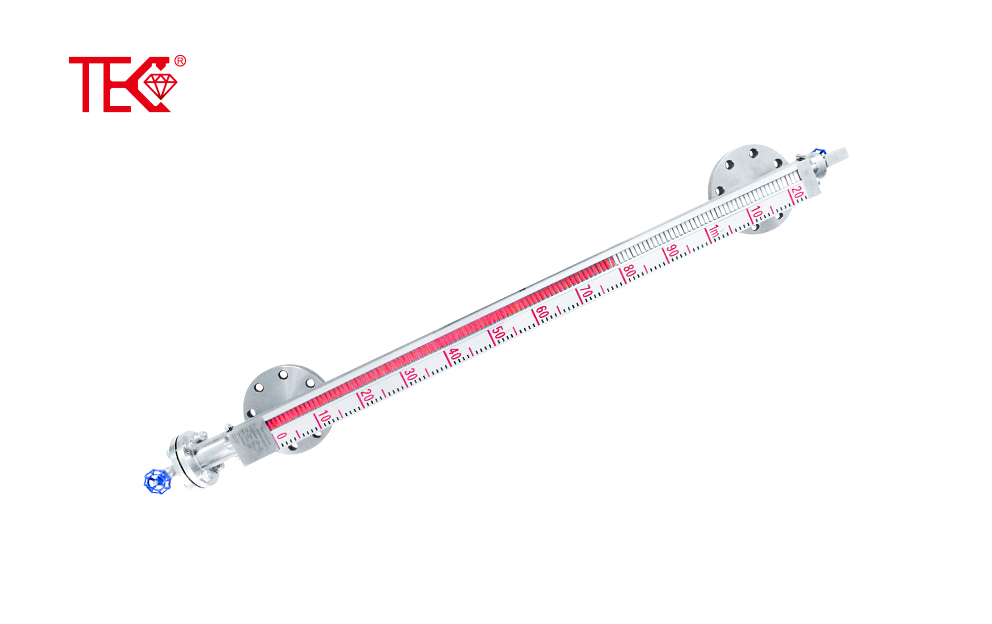

The prevention of industrial disasters begins with uncompromising accuracy in monitoring. Magnetostrictive liquid level gauges operate on a sophisticated principle that delivers exceptional precision. A magnetic float, which moves with the liquid surface, interacts with a ferromagnetic wire inside a probe. When a current pulse is sent down this wire, it creates a torsional stress wave at the point of the float's magnetic field. The time difference between the pulse initiation and the wave's return is measured with astonishing accuracy. This non-contact, wear-free method provides continuous, reliable data on liquid level, temperature, and interface, forming the first and most crucial line of defense against overfills, leaks, and process deviations.

How This Technology Actively Thwarts Catastrophic Failures

The true value of this technology is revealed in its proactive disaster prevention capabilities. By delivering highly accurate and stable data, these gauges empower control systems to act before a situation becomes critical. In a large fuel storage tank, for instance, the system can trigger an alarm and automatically shut down inflow pumps well before an overfill occurs, preventing a potential fire or environmental contamination. For chemical reactors, precise level control is essential to maintaining reaction integrity and preventing runaway reactions. The robust design of magnetostrictive gauges, often featuring no moving parts in direct contact with the process fluid, ensures long-term reliability and minimizes the risk of sudden sensor failure that could lead to a blind operational state.

Integrating Advanced Gauges into Your Overall Safety Protocol

Adopting magnetostrictive level measurement is a strategic decision for enhancing a plant's safety instrumented system (SIS). These devices provide the reliable data required by safety controllers to initiate predefined shutdown sequences. Their high resolution and fast response time are critical for dynamic processes where level changes can be rapid. Furthermore, their digital output and compatibility with modern control networks facilitate seamless integration into distributed control systems (DCS) and programmable logic controllers (PLC). This creates a cohesive safety ecosystem where data from the level gauge is not just monitored but is an active participant in a layered protection strategy, ensuring that multiple independent safeguards are in place.

The Tangible Benefits: Beyond Mere Compliance

Moving beyond regulatory compliance, the deployment of magnetostrictive liquid level gauges delivers profound operational and financial benefits. The prevention of a single incident can save a company millions in cleanup costs, regulatory fines, and reputational damage. The enhanced process control leads to reduced product loss, optimized inventory management, and improved overall efficiency. The longevity and minimal maintenance requirements of these systems also contribute to a lower total cost of ownership. By investing in this advanced level measurement technology, industries are not just checking a box for safety; they are building a foundation for sustainable, reliable, and profitable operations, ensuring that both people and assets are protected from unforeseen disasters.

UpgradingYourLevelMeasurementS

UpgradingYourLevelMeasurementS

Why are magnetostrictive level

Why are magnetostrictive level

ComparingMagnetostrictiveandRa

ComparingMagnetostrictiveandRa

MagnetostrictiveLevelSensorfor

MagnetostrictiveLevelSensorfor