How to enable multi-tank centralized monitoring with magnetostrictive technology?

In today's industrial landscape, efficient liquid management across multiple storage tanks has become crucial for operational excellence and cost optimization. Centralized monitoring systems provide a comprehensive solution to this challenge, offering real-time visibility and control over entire tank farms from a single interface. This approach eliminates the need for manual measurements and scattered data collection, transforming how industries manage their liquid assets.

Understanding Magnetostrictive Technology Fundamentals

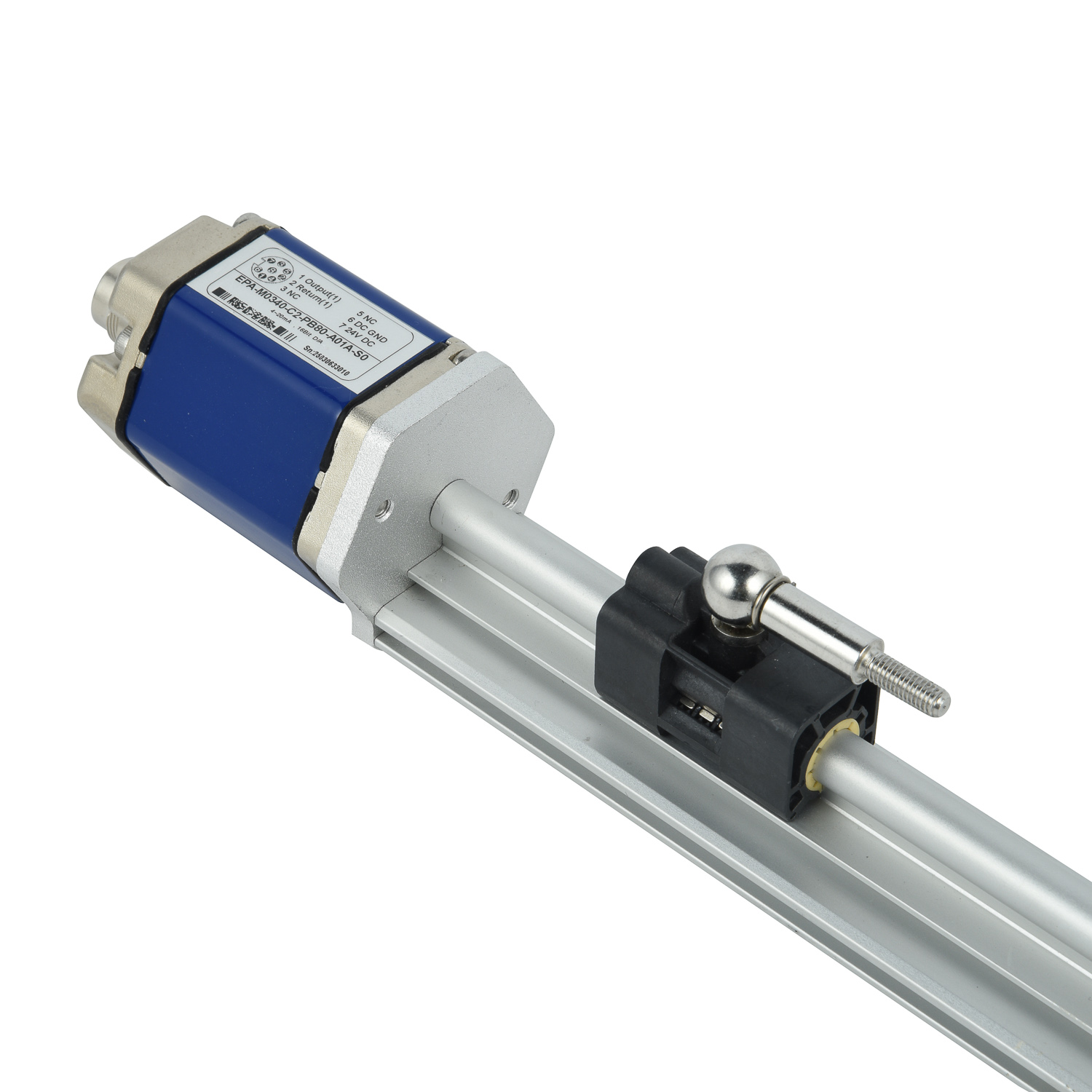

Magnetostrictive level sensors operate on a sophisticated physical principle where a magnetic field interacts with a waveguide to generate precise position measurements. The technology utilizes the magnetostrictive effect, where ferromagnetic materials change their shape when exposed to magnetic fields. A current pulse sent through the waveguide creates a torsional stress wave when it encounters the magnetic field from a float-mounted permanent magnet. By measuring the time delay between the pulse initiation and wave detection, these sensors achieve remarkable accuracy in determining liquid levels, typically within millimeter-range precision.

Key Components for Multi-Tank Systems

Implementing a centralized monitoring system requires several critical components working in harmony. Multiple magnetostrictive probes installed in each tank serve as the primary data collection points, each capable of measuring both level and temperature simultaneously. These sensors connect to a centralized control unit through appropriate interface modules that handle signal conditioning and data processing. The system incorporates communication gateways supporting industrial protocols like Modbus, Profibus, or Ethernet/IP for seamless integration with SCADA systems. Robust cabling infrastructure and power supply units complete the physical setup, ensuring reliable operation across the entire tank farm.

System Integration and Configuration

Successful integration begins with proper network architecture planning, determining whether to use star, ring, or bus topology based on facility layout and reliability requirements. Each magnetostrictive sensor must be calibrated according to tank specifications and liquid characteristics, with programming of appropriate measurement ranges and alarm thresholds. The centralized software platform requires configuration to recognize all tank assets, establish user access levels, and set up automated reporting protocols. Integration with existing enterprise systems such as ERP or maintenance management platforms enables comprehensive data utilization across organizational functions.

Real-Time Data Acquisition Process

The data acquisition cycle begins with each magnetostrictive sensor continuously measuring the position of the magnetic float along the waveguide. These measurements convert into digital signals containing level, temperature, and diagnostic information. The sensors transmit this data to collection nodes at predetermined intervals, typically ranging from milliseconds to seconds depending on process criticality. The central processing unit aggregates information from all tanks, performing validity checks and unit conversions before storing it in historical databases. Advanced systems incorporate timestamp synchronization to ensure all measurements reflect the same moment in time, crucial for accurate inventory reconciliation and process control.

Centralized Monitoring Interface Features

Modern monitoring interfaces provide comprehensive visualization tools through customizable dashboards that display key performance indicators across the entire tank farm. These platforms feature real-time trend graphs showing level variations, temperature profiles, and consumption rates for individual tanks or grouped assets. Automated alert systems trigger immediate notifications when levels approach predefined thresholds, with escalation protocols for critical situations. The software generates comprehensive reports including inventory summaries, consumption patterns, and exception reports, while maintenance modules track sensor health and predict calibration requirements.

Accuracy and Reliability Advantages

Magnetostrictive technology delivers exceptional measurement consistency with typical accuracy of ±0.05% of full scale and repeatability within 0.01% across operational cycles. The non-contact measurement principle ensures minimal wear on components, resulting in extended service life exceeding 10 years in most applications. These sensors maintain performance stability despite changing process conditions such as density variations, foam layers, or temperature fluctuations. Built-in self-diagnostic capabilities continuously monitor sensor health, detecting potential issues like electronic drift or mechanical problems before they affect measurement reliability.

Implementation Best Practices

Proper implementation begins with thorough site assessment, evaluating environmental conditions, accessibility requirements, and potential interference sources. Sensor selection must consider chemical compatibility with stored liquids, pressure and temperature ranges, and appropriate mounting configurations. Installation requires careful attention to mounting orientation, ensuring proper alignment and avoiding areas with excessive turbulence or material buildup. Cable routing should follow separation guidelines to minimize electromagnetic interference, with appropriate surge protection for lightning-prone areas. Commissioning involves comprehensive functional testing under various operating conditions to verify system performance before operational deployment.

Maintenance and Troubleshooting Protocols

Proactive maintenance schedules should include regular visual inspections for physical damage, connector integrity checks, and verification of calibration stability. Diagnostic software tools monitor performance metrics like signal strength, response time, and temperature readings to identify developing issues. Common troubleshooting scenarios address communication failures through systematic checks of network connectivity, power supply stability, and gateway functionality. For measurement inaccuracies, technicians verify float movement freedom, check for material buildup, and validate calibration parameters. Most magnetostrictive sensors feature modular designs enabling component-level replacement without complete system shutdown.

Future Trends and Innovations

The evolution of magnetostrictive monitoring systems continues with emerging technologies enhancing their capabilities. Wireless connectivity options using industrial IoT protocols reduce installation complexity while maintaining data reliability. Advanced analytics platforms incorporate machine learning algorithms to predict consumption patterns, detect anomalies, and optimize replenishment schedules. Integration with cloud platforms enables remote monitoring capabilities and centralized management of geographically dispersed facilities. Next-generation sensors are incorporating additional measurement parameters including density, interface detection, and water content analysis, expanding their application scope across various industrial processes.

UpgradingYourLevelMeasurementS

UpgradingYourLevelMeasurementS

Why are magnetostrictive level

Why are magnetostrictive level

ComparingMagnetostrictiveandRa

ComparingMagnetostrictiveandRa

MagnetostrictiveLevelSensorfor

MagnetostrictiveLevelSensorfor