How to implement multi-language display in magnetostrictive level gauges?

Implementing multi-language functionality in magnetostrictive level gauges represents a significant advancement in industrial instrumentation, particularly for facilities operating across international borders. This capability ensures that operators with different language preferences can efficiently monitor and manage liquid level measurements without interpretation barriers. The growing globalization of industrial operations makes this feature not just convenient but essential for maintaining operational efficiency and safety standards across diverse workforce demographics.

Understanding Magnetostrictive Technology Fundamentals

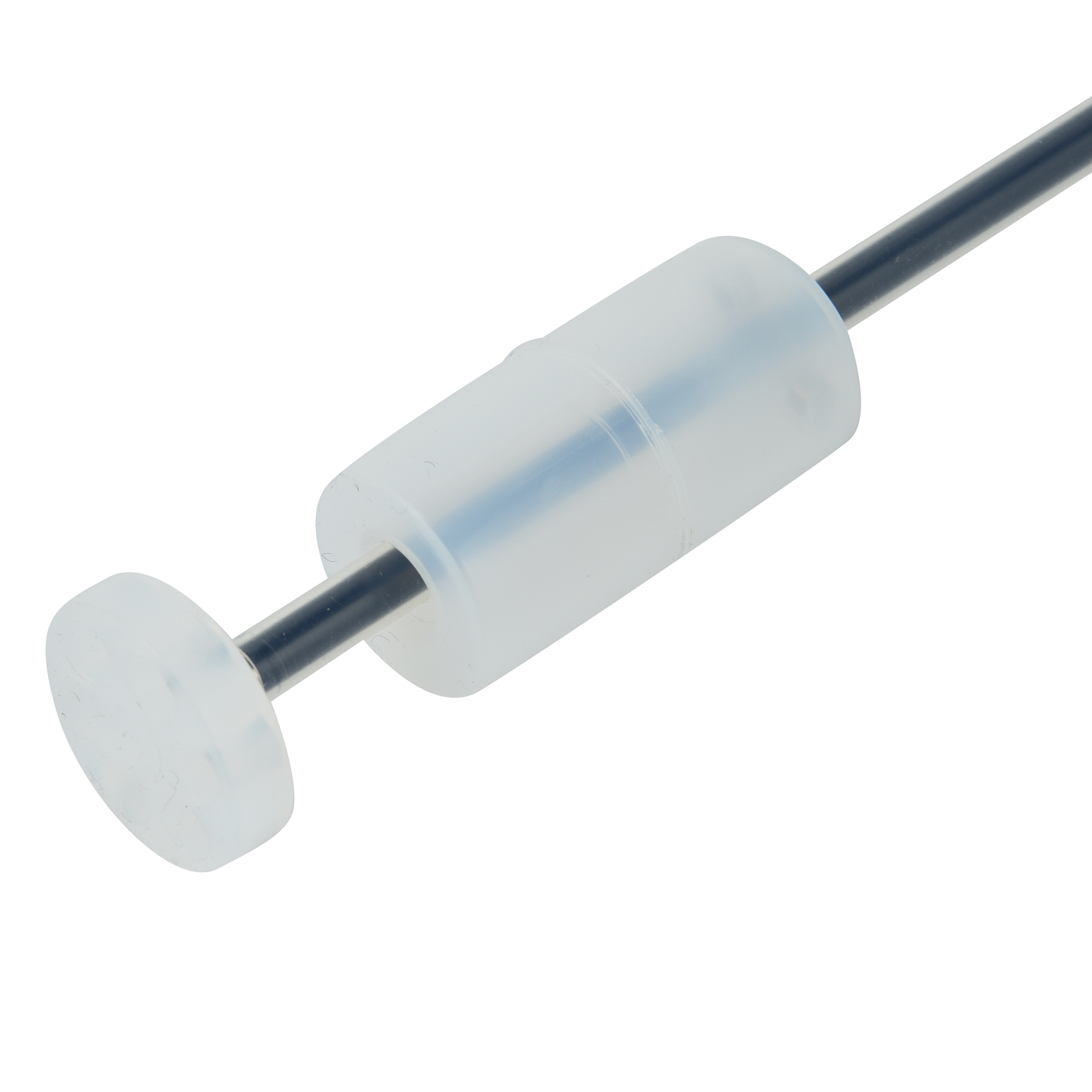

Magnetostrictive level gauges operate through a sophisticated principle where a magnetic float, positioned along a measuring rod, interacts with a torsion wave generated by an electrical pulse. The time difference between wave transmission and return signal precisely determines liquid level position. This technology's inherent accuracy and reliability make it ideal for critical applications across various industries, from chemical processing to oil and gas operations. The digital nature of these instruments provides an excellent foundation for implementing advanced features like multi-language support without compromising measurement integrity.

HMI Configuration for Language Implementation

The primary method for enabling multi-language displays involves configuring the Human-Machine Interface (HMI) software that accompanies magnetostrictive level gauges. Most modern gauges include proprietary configuration tools that allow engineers to embed multiple language packages directly into the device firmware. This process typically involves accessing the configuration menu, selecting language options, and uploading corresponding translation files. Manufacturers often provide standardized templates for common languages, including English, Spanish, Chinese, and Arabic, significantly simplifying the implementation process for technical teams.

Software Tools and Programming Approaches

Advanced implementation may require specialized software tools provided by gauge manufacturers. These applications typically feature resource editors that enable the creation and management of multiple language libraries. Through structured programming interfaces, engineers can define text strings for various display elements—including menu options, error messages, and unit indicators—in multiple languages. The software automatically switches between language sets based on operator selection, ensuring consistent user experience regardless of the chosen display language. This approach maintains the gauge's core functionality while providing linguistic flexibility.

Practical Implementation Strategies

Successful deployment begins with comprehensive planning, identifying all display elements requiring translation, including calibration prompts, unit designations, and diagnostic messages. Technical teams should create a complete string inventory before commencing translation work. Implementation typically follows a structured process: first, exporting existing display text; second, professional translation of all interface elements; third, rigorous testing of each language option; and finally, deployment across all relevant instruments. This systematic approach prevents operational disruptions and ensures translation accuracy across all interface components.

Troubleshooting Common Implementation Challenges

During implementation, several challenges may emerge, including character encoding inconsistencies, text truncation in translated versions, and firmware compatibility issues. These can be mitigated through thorough testing cycles that verify all language displays under various operational scenarios. Particular attention should be paid to languages with unique character sets or right-to-left reading directions, ensuring proper alignment and readability. Additionally, maintaining original language files as reference points helps quickly resolve any display abnormalities that might occur during the transition period.

Best Practices for Maintenance and Updates

Establishing a documentation system for all language implementations ensures long-term maintainability. This includes version control for language files, change logs for all modifications, and regular audits of display accuracy. When updating gauge firmware or adding new measurement parameters, corresponding updates to all language files should be implemented simultaneously. Creating standardized procedures for these maintenance activities prevents language display inconsistencies and ensures all operators receive identical information regardless of their selected interface language.

Future Developments in Multi-Language Instrumentation

The evolution of multi-language capabilities in industrial instruments continues advancing, with emerging technologies like cloud-based translation services and AI-powered localization tools offering promising enhancements. Future magnetostrictive level gauges may feature automatic language detection or voice-based interface options, further simplifying operation across linguistic boundaries. These developments will continue breaking down language barriers in industrial environments, promoting safety and efficiency through improved human-machine interaction regardless of operators' native languages.

UpgradingYourLevelMeasurementS

UpgradingYourLevelMeasurementS

Why are magnetostrictive level

Why are magnetostrictive level

ComparingMagnetostrictiveandRa

ComparingMagnetostrictiveandRa

MagnetostrictiveLevelSensorfor

MagnetostrictiveLevelSensorfor