Why are magnetostrictive sensors more vibration-resistant?

In the demanding world of industrial automation and machinery, sensors must perform reliably under harsh conditions. Among these, vibration presents a significant challenge to the accuracy and longevity of many sensing technologies. This is where magnetostrictive sensors distinguish themselves, offering a level of vibration resistance that is often superior to alternative solutions like potentiometric or optical encoders. Their inherent robustness makes them the preferred choice for critical position and level sensing applications where stability is non-negotiable.

The Core Principle: Immunity from Mechanical Wear

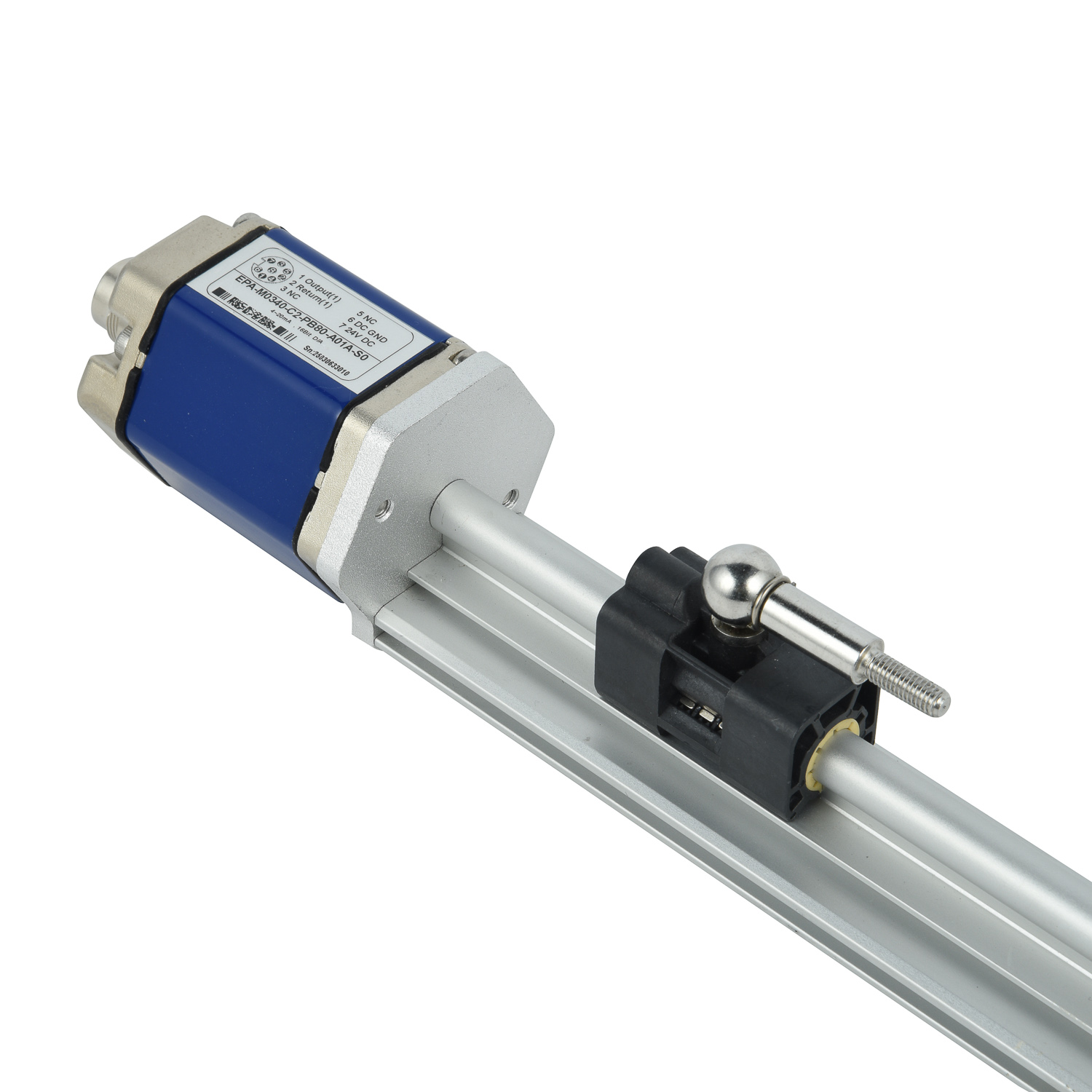

The fundamental reason for the exceptional vibration resistance of magnetostrictive sensors lies in their non-contact operating principle. These sensors measure position by detecting the precise interaction between a magnetic field (from a moving magnet) and a torsion wave propagating along a sealed waveguide. Since the position magnet is the only moving part and it does not physically contact the sensor body, there is no mechanical linkage to be affected by vibrations. This starkly contrasts with sensors that rely on sliding contacts or mechanical gears, which can wear out, become misaligned, or generate noise when subjected to constant shaking, leading to measurement drift and eventual failure.

Rugged Construction for Demanding Environments

Beyond their non-contact principle, magnetostrictive sensors are built to withstand physical stress. The sensing element, the waveguide, is typically housed within a robust, hermetically sealed stainless steel tube. This construction protects the sensitive internal components from external contaminants like dust, moisture, and oil, which are often present in vibrating environments. Furthermore, the electronics are potted or encapsulated to shield them from shock and high-frequency vibrations that could otherwise loosen solder joints or damage components. This durable packaging ensures signal integrity and long-term reliability even when mounted directly on heavy machinery.

Superior Signal Processing and Filtering

Modern magnetostrictive sensors incorporate advanced signal processing electronics designed to differentiate the desired measurement signal from vibrational noise. The torsional wave generated by the magnet's position has a distinct signature. Sophisticated filtering algorithms can effectively isolate this signal from the background mechanical noise induced by vibration. This electronic immunity allows the sensor to maintain high accuracy and repeatability, providing a stable and clean output signal that control systems can depend on, regardless of the ambient conditions.

A Clear Advantage Over Other Sensor Technologies

When compared to other common position sensors, the benefits of magnetostrictive technology in vibratory applications become clear. Linear Variable Differential Transformers (LVDTs), while accurate, can have issues with the wear of their bearing systems. Potentiometers suffer from wiper contact degradation. Optical encoders are highly susceptible to contamination from dust or oil mist, which can obscure their scales. Magnetostrictive sensors effectively bypass these failure modes, offering a combination of high precision, longevity, and resilience that is ideally suited for challenging industrial settings.

Conclusion: The Go-To Solution for Stability

In summary, magnetostrictive sensors are more vibration-resistant due to a powerful combination of a wear-free, non-contact measurement principle, a rugged physical design that shrugs off environmental insults, and intelligent signal processing that filters out noise. For engineers and designers seeking a reliable and precise sensing solution for applications involving pumps, hydraulic cylinders, presses, or any machinery with significant vibration, magnetostrictive technology provides the dependable performance required to ensure operational continuity and safety.

UpgradingYourLevelMeasurementS

UpgradingYourLevelMeasurementS

Why are magnetostrictive level

Why are magnetostrictive level

ComparingMagnetostrictiveandRa

ComparingMagnetostrictiveandRa

MagnetostrictiveLevelSensorfor

MagnetostrictiveLevelSensorfor