Why are magnetostrictive sensors better for confined space installations?

When it comes to industrial sensing applications in tight quarters, magnetostrictive sensors offer distinct advantages that make them the superior choice for engineers and technicians. Their unique operating principle and robust design characteristics provide reliable performance where other sensor technologies often fall short. Let's explore the specific reasons why these sensors are particularly well-suited for challenging confined space installations.

Superior Non-Contact Measurement Technology

Magnetostrictive sensors operate using a non-contact principle that eliminates mechanical wear and maintenance issues common in confined environments. A magnetic field interacts with a waveguide to determine position or level without physical contact with the measured medium. This technology ensures long-term reliability in spaces where maintenance access is limited or hazardous. The absence of mechanical components means there are no parts to wear out, making these sensors ideal for permanent installations in hard-to-reach areas.

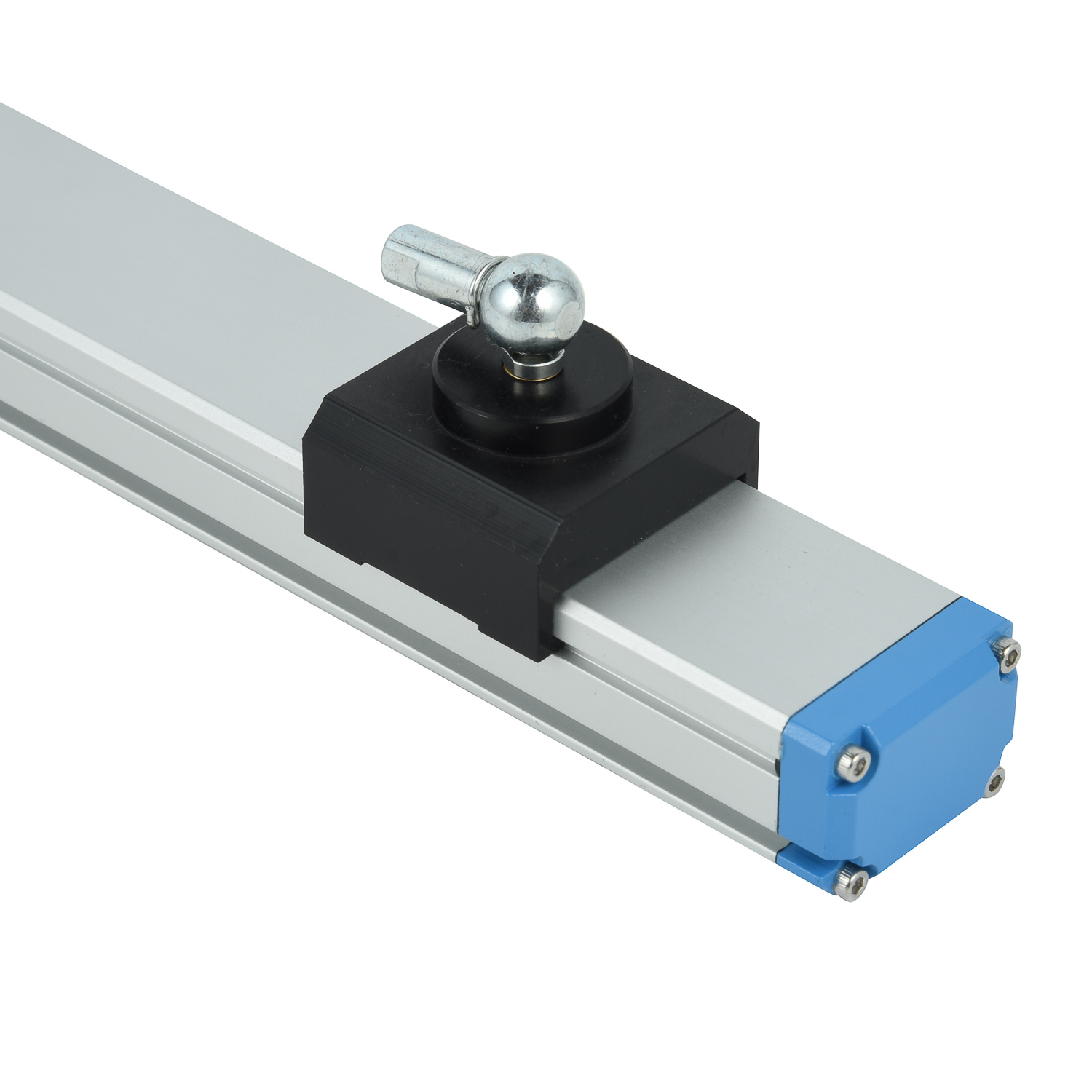

Compact Design for Space-Constrained Applications

The slender, cylindrical form factor of magnetostrictive sensors allows installation in extremely tight spaces where other sensing technologies simply wouldn't fit. With diameters often less than 20mm and the ability to provide precise measurements over long ranges, these sensors solve spatial challenges without compromising performance. Their minimal footprint enables integration into existing systems with minimal modification, reducing installation time and costs in cramped industrial settings.

Exceptional Performance in Hazardous Environments

Magnetostrictive sensors maintain accuracy and reliability even when exposed to extreme temperatures, high pressures, and corrosive materials commonly found in confined industrial spaces. Many models carry explosion-proof certifications and can operate safely in potentially explosive atmospheres. This rugged construction ensures continuous operation where safety concerns might prevent using other sensing technologies, providing peace of mind in critical applications.

Simplified Installation and Reduced Maintenance

The straightforward installation process of magnetostrictive sensors makes them particularly valuable in confined spaces where complex procedures are impractical. With minimal calibration requirements and no need for regular adjustments, these sensors significantly reduce the time technicians must spend in potentially dangerous confined areas. Their proven durability translates to fewer replacements and service interruptions, optimizing operational efficiency in challenging environments.

High Accuracy Despite Spatial Limitations

Unlike some technologies that sacrifice precision when miniaturized, magnetostrictive sensors deliver exceptional measurement accuracy regardless of their compact dimensions. They provide precise, repeatable measurements with resolutions down to micrometers, ensuring reliable data for process control even in the most space-restricted applications. This combination of small size and high performance makes them indispensable for modern industrial automation systems where every millimeter counts.

UpgradingYourLevelMeasurementS

UpgradingYourLevelMeasurementS

Why are magnetostrictive level

Why are magnetostrictive level

ComparingMagnetostrictiveandRa

ComparingMagnetostrictiveandRa

MagnetostrictiveLevelSensorfor

MagnetostrictiveLevelSensorfor