Why are magnetostrictive sensors the first choice for hydraulic systems?

In the demanding world of industrial hydraulics, precision and reliability are non-negotiable. Among the various sensing technologies available, magnetostrictive sensors have emerged as the undisputed leader for critical hydraulic applications. Their unique operating principle and robust design make them ideally suited for the harsh environments typically associated with hydraulic machinery. This article explores the compelling reasons why engineers consistently specify magnetostrictive technology for accurate position and velocity feedback in cylinders and actuators.

Unmatched Precision and Accuracy

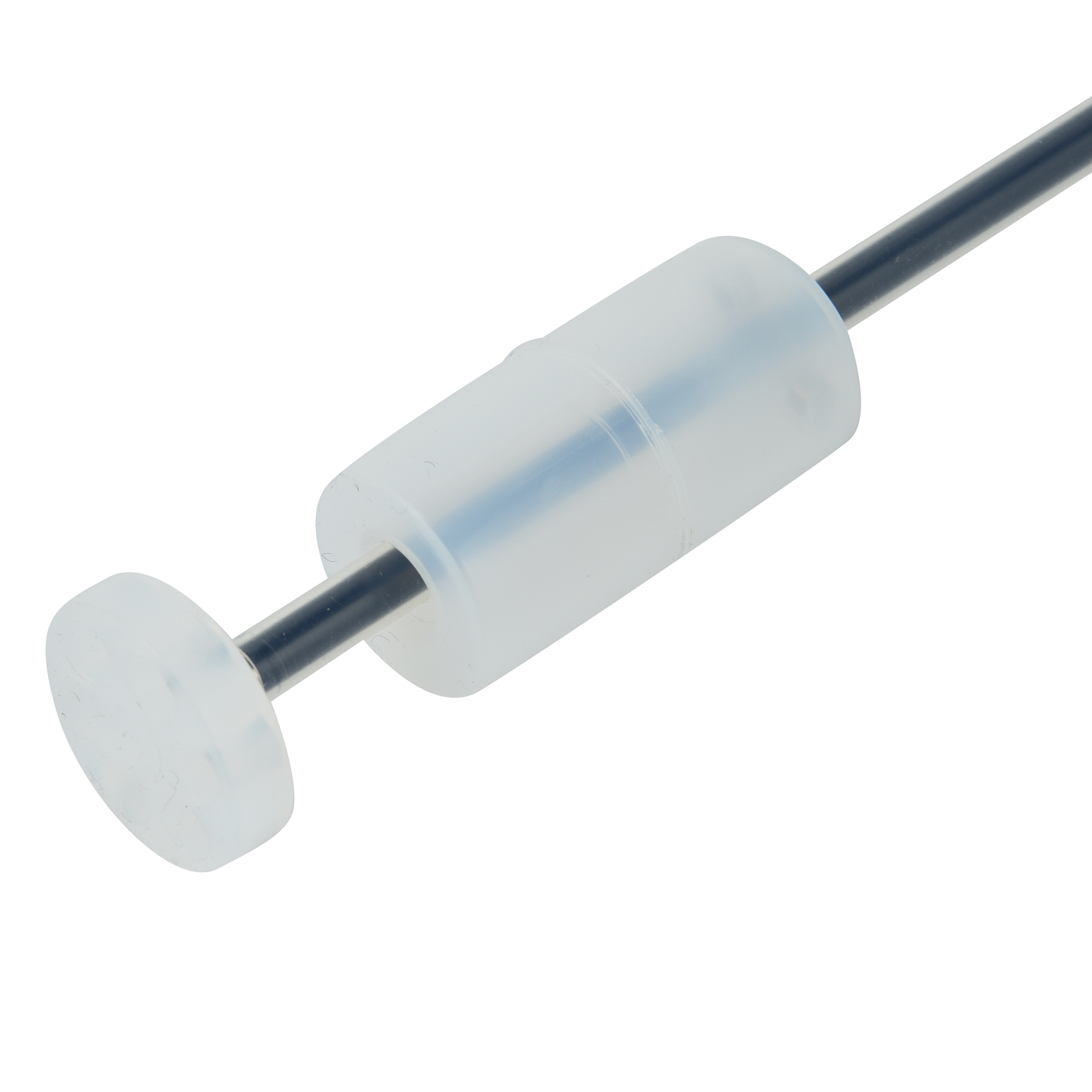

The fundamental advantage of magnetostrictive sensors lies in their exceptional measurement accuracy. Unlike potentiometric or other contact-based sensors, magnetostrictive sensors operate on a non-contact principle. They work by generating a torsional strain wave in a waveguide when the magnetic field from a position magnet interacts with a current pulse. The time-of-flight measurement of this wave provides a highly precise reading of the magnet's position. This technology enables resolutions down to micrometers and repeatability that is critical for applications like injection molding machines, press brakes, and steel mill equipment, where even a minute error can lead to significant quality issues or machine failure.

Exceptional Durability and Long Service Life

Hydraulic systems are notoriously harsh environments, characterized by high pressures, temperature extremes, shock, and vibration. Magnetostrictive sensors are built to thrive in these conditions. Their non-contact nature means there is no mechanical wear between the sensing element and the position magnet. The sensor is typically housed in a robust stainless steel tube, sealed to IP67 standards or higher, protecting the internal electronics from moisture, hydraulic fluid, and contaminants. This inherent ruggedness translates into a dramatically longer service life compared to linear potentiometers or LVDTs, reducing downtime and total cost of ownership.

Superior Reliability in Demanding Conditions

Reliability is paramount in industrial automation. Magnetostrictive sensors offer exceptional stability over time, with minimal drift. They are immune to common issues that plague other sensors, such as the wear and tear of wipers in potentiometers or the sensitivity to EMI in some magnetic encoders. The technology provides absolute position measurement, meaning the sensor retains its position data even after a power cycle, eliminating the need for re-homing sequences. This absolute feedback ensures that hydraulic systems can resume operation immediately and safely, a critical feature for automated processes.

Multifunctional Capabilities from a Single Sensor

A single magnetostrictive sensor can provide more than just linear position feedback. Advanced models can simultaneously deliver multiple outputs, including velocity, acceleration, and even the position of multiple magnets for complex cylinder applications. This multifunctionality consolidates what would otherwise require several discrete sensors, simplifying system design, reducing wiring complexity, and minimizing potential points of failure. This capability is invaluable for sophisticated hydraulic systems where synchronized movement and precise control of multiple actuators are necessary.

Conclusion: The Clear Choice for High-Performance Hydraulics

When the application demands the highest levels of accuracy, durability, and reliability, magnetostrictive sensors stand out as the optimal solution for hydraulic systems. Their non-contact operation ensures long-term stability, while their robust construction withstands the toughest industrial environments. By providing critical data for precise control, these sensors contribute directly to improved machine performance, product quality, and operational safety. For engineers designing the next generation of hydraulic equipment, magnetostrictive technology remains the first and most logical choice.

UpgradingYourLevelMeasurementS

UpgradingYourLevelMeasurementS

Why are magnetostrictive level

Why are magnetostrictive level

ComparingMagnetostrictiveandRa

ComparingMagnetostrictiveandRa

MagnetostrictiveLevelSensorfor

MagnetostrictiveLevelSensorfor