TheUltimateBuyer'sGuideforHigh-AccuracyMagnetostrictiveDisplacementSensors2024

Understanding Magnetostrictive Displacement Sensor Technology

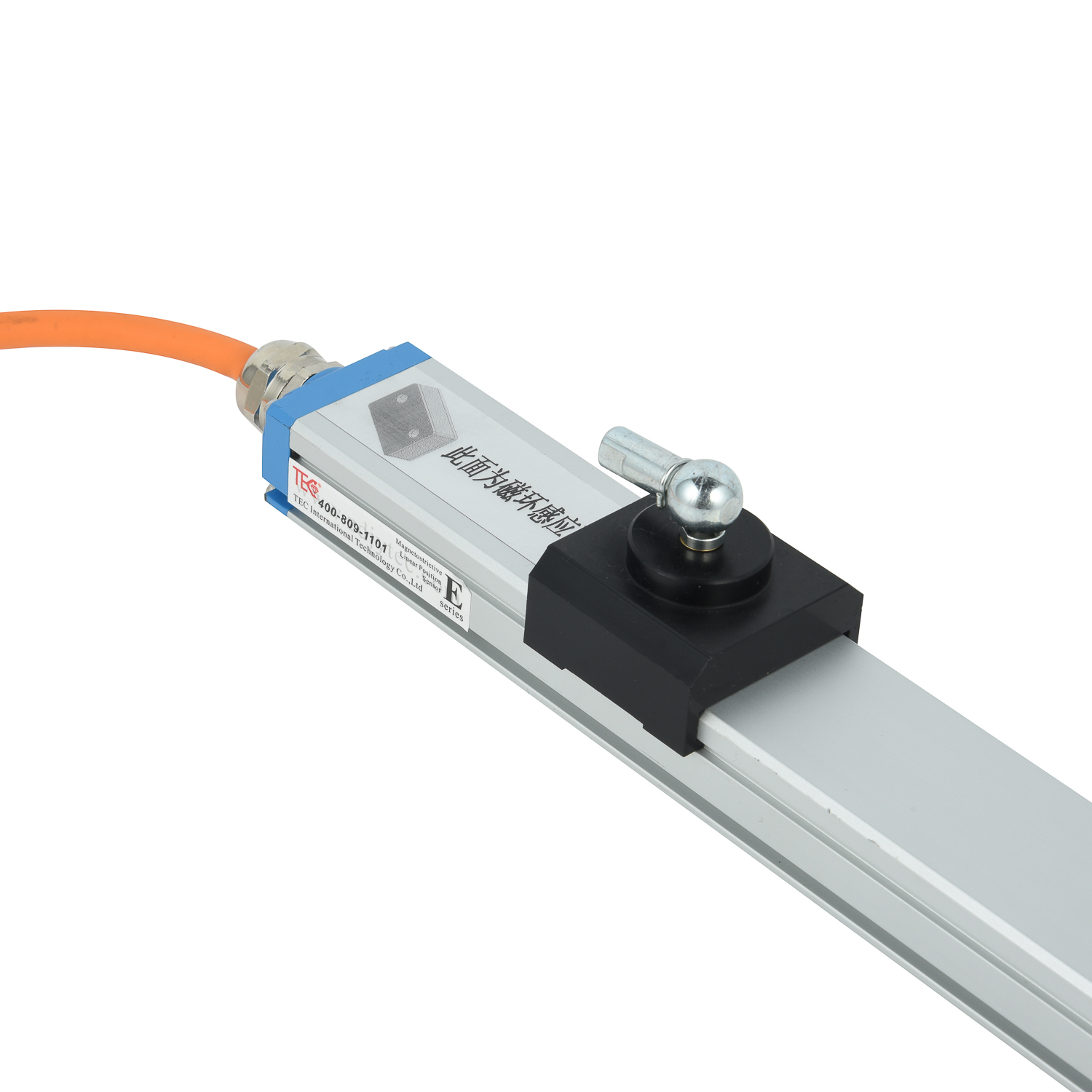

Magnetostrictive displacement sensors represent the pinnacle of precision measurement technology, utilizing the interaction between magnetic fields and magnetostrictive materials to achieve exceptional accuracy. These sensors operate based on the magnetostrictive principle where a temporary torsional strain wave is generated when two magnetic fields interact. The time taken for this wave to travel along a waveguide wire is measured with nanosecond precision, enabling position detection with resolutions up to 0.001% of full scale. This non-contact measurement technology ensures virtually infinite resolution without any mechanical wear, making it ideal for applications requiring both high precision and long-term reliability. The fundamental physics behind this technology allows for absolute position measurement without the need for homing routines after power interruptions.

Key Advantages Over Other Sensor Technologies

When compared to alternative displacement measurement technologies, magnetostrictive sensors offer distinct advantages that justify their premium positioning in the market. Unlike LVDT sensors that require physical contact or optical encoders that are sensitive to contamination, magnetostrictive sensors provide non-contact operation with exceptional immunity to harsh industrial environments. They outperform potentiometric sensors in lifespan by eliminating mechanical wear and surpass ultrasonic sensors in precision, particularly in applications with varying environmental conditions. The ability to provide absolute position measurement immediately upon power-up gives them a significant advantage over incremental encoders that require reference runs. Additionally, their robust construction typically offers IP67 or higher protection ratings, making them suitable for hydraulic applications where they might be exposed to fluids and high pressures.

Critical Selection Criteria for Your Application

Selecting the appropriate magnetostrictive displacement sensor requires careful consideration of several technical parameters to ensure optimal performance in your specific application. Measurement range stands as the primary consideration, with available options spanning from 50mm to 3000mm to accommodate different machinery dimensions. Resolution requirements must be evaluated, with high-precision applications often needing 1μm or better resolution while standard applications may function adequately with 10μm resolution. The output interface represents another crucial decision point, with choices including analog outputs (4-20mA, 0-10V), start-stop interfaces, and various digital protocols such as SSI, CANopen, or PROFIBUS. Environmental factors including temperature range, vibration resistance, and ingress protection rating must align with the operating conditions, while mechanical considerations like housing material and connection type ensure proper integration with existing equipment.

Installation Best Practices and Configuration Tips

Proper installation profoundly impacts the performance and longevity of magnetostrictive displacement sensors, making adherence to best practices essential for optimal results. Mechanical alignment must be precise, with the position magnet moving parallel to the sensor tube within specified tolerances to prevent measurement errors. Electrical installation requires careful attention to grounding and shielding to minimize noise interference, particularly in environments with variable frequency drives or welding equipment. Configuration procedures should follow manufacturer guidelines for calibration and parameter setting, with particular attention to setting the measurement range and output characteristics to match the control system requirements. Regular maintenance should include periodic checks of mounting stability, connector integrity, and magnet condition, especially in high-vibration applications where hardware may loosen over time.

Industry Applications and Implementation Examples

Magnetostrictive displacement sensors find extensive application across numerous industries where precision linear position measurement is critical to process quality and equipment performance. In hydraulic cylinder positioning, these sensors provide feedback for proportional valve control in injection molding machines and plastic extrusion equipment. The steel industry employs them for exact position control in rolling mills, while mobile equipment manufacturers integrate them into hydraulic cylinders for grader blades and loader attachments. Automation systems utilize these sensors for robotic positioning and material handling equipment, where their absolute measurement capability ensures reliable operation without homing sequences. Test and measurement applications benefit from their high precision in fatigue testing machines and quality control instrumentation.

Future Trends and Technology Developments

The magnetostrictive sensor market continues to evolve with emerging technologies that enhance performance while addressing industry demands for connectivity and intelligence. Integration of IO-Link communication capabilities represents a significant trend, enabling advanced diagnostics, parameterization, and condition monitoring features. Miniaturization efforts are producing compact sensors for space-constrained applications without compromising measurement accuracy. Enhanced materials science is developing waveguides with improved temperature stability, expanding operational ranges to extreme environments exceeding 150°C. Wireless connectivity options are emerging for applications where cabling proves impractical, while cybersecurity features are being incorporated into networked sensors to protect industrial control systems from potential vulnerabilities.

UpgradingYourLevelMeasurementS

UpgradingYourLevelMeasurementS

Why are magnetostrictive level

Why are magnetostrictive level

ComparingMagnetostrictiveandRa

ComparingMagnetostrictiveandRa

MagnetostrictiveLevelSensorfor

MagnetostrictiveLevelSensorfor