ImproveInventoryManagementwithMagnetostrictiveTankGauging

In today's competitive industrial landscape, accurate inventory management has become paramount for operational excellence and financial accountability. Precise knowledge of material quantities enables better decision-making, reduces losses, and enhances overall efficiency. Traditional measurement methods often fall short in delivering the reliability needed for modern operations, creating a pressing need for advanced technological solutions that can provide real-time, accurate data without constant manual intervention.

Understanding Magnetostrictive Tank Gauging

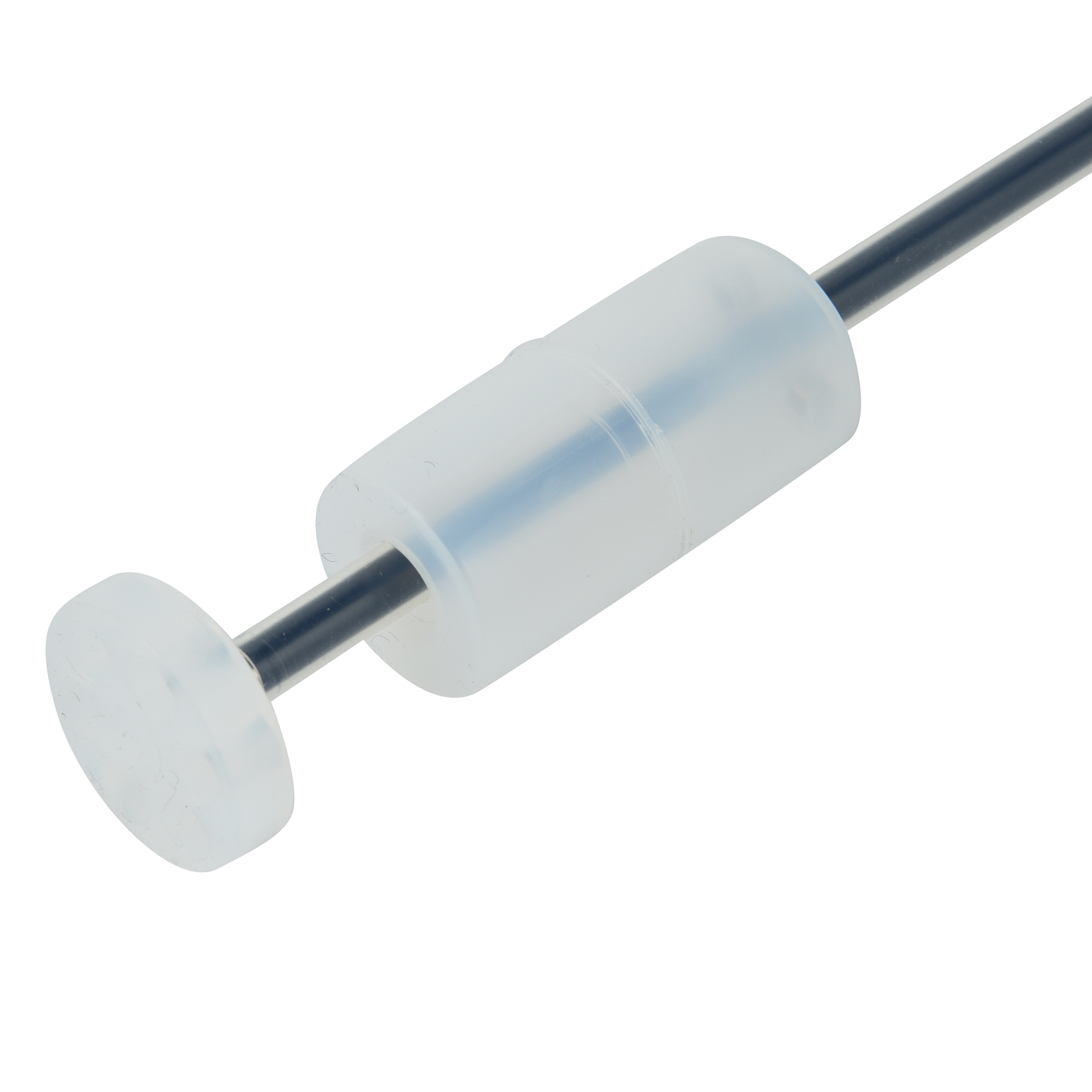

Magnetostrictive tank gauging represents a significant technological advancement in liquid level measurement systems. This sophisticated method utilizes a magnetic float that moves along a wire within a sealed tube, generating precise position data through the interaction of magnetic fields. The system calculates level by measuring the time difference between applied current pulses and returning torsional waves, delivering exceptional accuracy even in challenging industrial environments. This non-contact measurement approach eliminates many common issues associated with mechanical gauges, providing reliable data for critical inventory decisions.

Enhanced Accuracy for Better Inventory Control

The implementation of magnetostrictive technology brings unprecedented precision to inventory management processes. These systems consistently achieve accuracy levels within ±0.5mm, dramatically reducing measurement uncertainties that traditionally plagued inventory calculations. This precision translates directly to financial benefits through minimized product loss, improved custody transfer operations, and more reliable accounting practices. Companies utilizing this technology report significant reductions in inventory discrepancies, enabling better forecasting and more efficient supply chain management while complying with stringent industry regulations.

Streamlining Operations with Real-Time Data

Modern magnetostrictive gauging systems integrate seamlessly with facility control networks, providing continuous real-time data to operators and management systems. This instantaneous access to accurate inventory information enables proactive decision-making and rapid response to changing conditions. Automated alerts notify personnel of potential issues before they escalate, while historical data tracking facilitates trend analysis and predictive maintenance scheduling. The elimination of manual tank dipping and associated safety risks further enhances operational efficiency while reducing labor costs and exposure to hazardous materials.

Reducing Operational Costs and Risks

The financial advantages of implementing magnetostrictive tank gauging extend far beyond improved inventory accuracy. These systems significantly decrease operational expenses through reduced manual measurement requirements, minimized product loss from measurement errors, and prevention of costly overfill or run-dry situations. Enhanced safety features help avoid environmental incidents and associated regulatory penalties, while the reduced need for personnel to access potentially hazardous tank areas decreases insurance premiums and improves overall workplace safety metrics.

Integration with Modern Inventory Systems

Contemporary magnetostrictive gauging solutions offer comprehensive integration capabilities with existing inventory management and enterprise resource planning systems. This seamless connectivity ensures that accurate tank level data automatically updates inventory records, eliminating manual data entry errors and delays. The technology supports various communication protocols including HART, Foundation Fieldbus, and Profibus, allowing flexible implementation across diverse industrial environments. This interoperability enables complete supply chain visibility and facilitates automated replenishment processes based on actual consumption patterns.

Future-Proofing Your Inventory Management

As industrial operations continue evolving toward greater automation and digitalization, magnetostrictive tank gauging technology provides a solid foundation for future expansion. These systems readily incorporate emerging technologies like IoT connectivity, cloud-based analytics, and artificial intelligence applications. The scalable architecture supports additional measurement parameters including temperature, density, and volume, offering comprehensive tank inventory information through a single integrated system. This forward compatibility ensures that investments in magnetostrictive technology continue delivering value as operational requirements evolve and expand.

UpgradingYourLevelMeasurementS

UpgradingYourLevelMeasurementS

Why are magnetostrictive level

Why are magnetostrictive level

ComparingMagnetostrictiveandRa

ComparingMagnetostrictiveandRa

MagnetostrictiveLevelSensorfor

MagnetostrictiveLevelSensorfor