IndustrialTankLevelControlUsingMagnetostrictiveGauges

In modern industrial operations, precise tank level monitoring represents a critical component of process efficiency and safety. Magnetostrictive level sensors have emerged as the gold standard for achieving unprecedented accuracy in liquid measurement applications across various industries. These advanced instruments combine reliability with technological sophistication to deliver continuous, real-time data that drives operational excellence.

Advanced Working Principle of Magnetostrictive Gauges

The operational foundation of magnetostrictive level sensors lies in the ingenious application of the magnetostrictive effect. These devices utilize a specialized waveguide wire constructed from magnetostrictive material, typically nickel-iron alloys, enclosed within a protective stainless steel tube. When an electrical current pulse interacts with magnetic fields generated by float-mounted permanent magnets, torsional stress waves propagate along the waveguide at precise velocities. Sophisticated electronic circuitry measures the time differential between pulse transmission and wave return, calculating exact float positions with resolutions reaching 0.001% of full scale. This non-contact measurement methodology ensures exceptional longevity and repeatability without mechanical wear components.

Unmatched Precision and Measurement Accuracy

Industrial facilities consistently choose magnetostrictive technology for its exceptional measurement capabilities that far surpass traditional float switches or capacitance-based systems. These sensors deliver remarkable accuracy levels within ±0.05% of full scale, maintaining consistent performance across diverse temperature ranges and process conditions. The technology's inherent immunity to dielectric constant variations, specific gravity changes, and process density fluctuations makes it particularly valuable for applications requiring exact inventory management or precise batching operations. Continuous analog output signals provide real-time level data without the stair-step limitations of discrete point measurements.

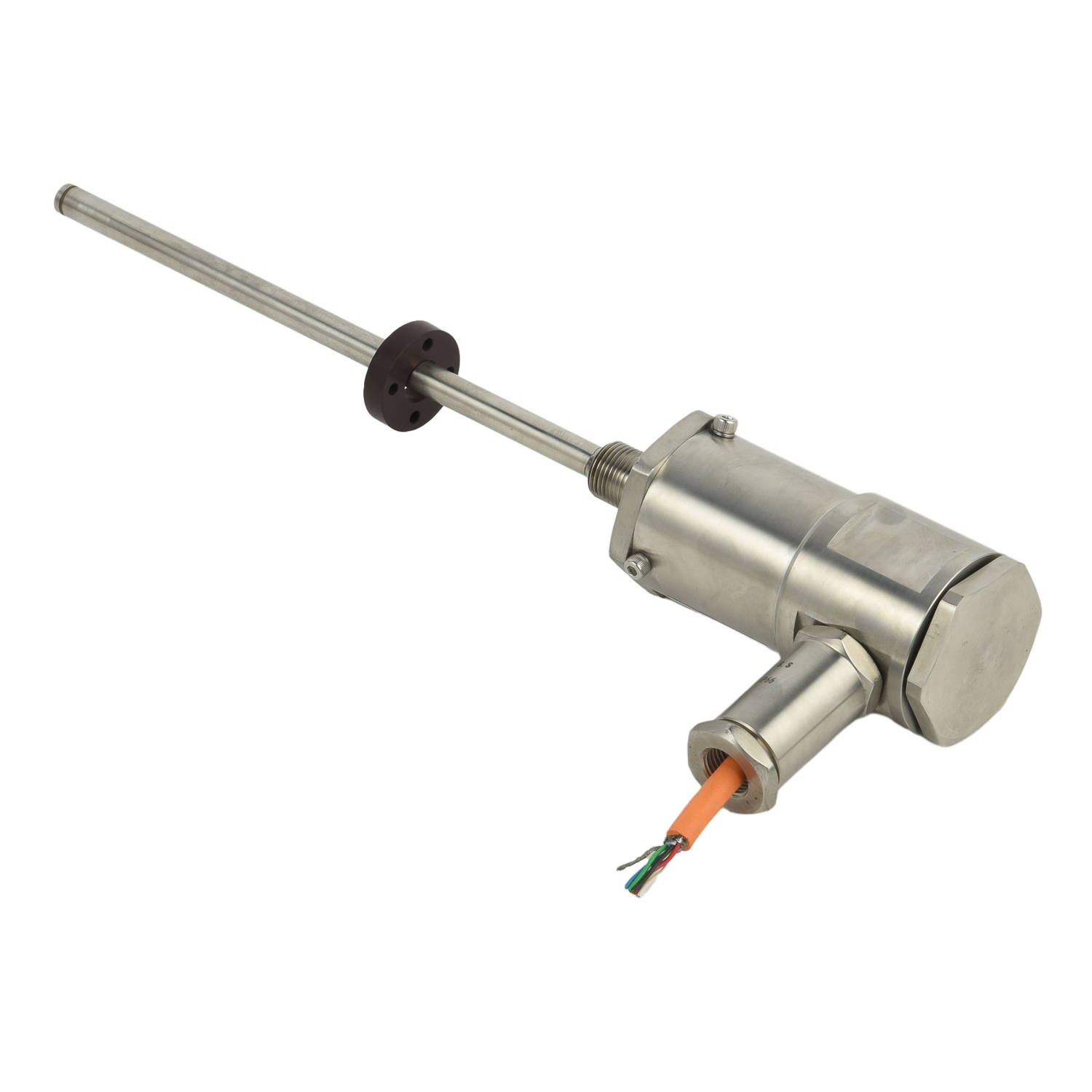

Robust Construction for Demanding Environments

Magnetostrictive level sensors excel in challenging industrial settings through their ruggedized design and material selection. Manufacturers typically construct these instruments using 316 stainless steel or Hastelloy bodies with multiple sealing options including FEP-encapsulated O-rings and welded hermetic seals. This robust construction enables reliable operation in extreme temperatures ranging from -196°C to 204°C and withstands pressure conditions up to 5800 psi. The non-contact sensing mechanism eliminates mechanical wear points, while the integrated electronics compartment often achieves IP67, IP69K, or NEMA 4X environmental protection ratings for reliable performance in corrosive or explosive atmospheres.

Seamless Control System Integration

Modern magnetostrictive level transmitters offer unparalleled integration flexibility with existing industrial automation architectures. These devices typically provide multiple output options including 4-20mA analog signals, HART protocol, PROFIBUS-PA, Foundation Fieldbus, and Modbus RTU communications. This connectivity versatility enables direct interface with PLC systems, DCS networks, and plant-wide SCADA systems without requiring additional signal conditioning equipment. Advanced diagnostic capabilities and remote configuration options further enhance system maintainability while reducing overall lifecycle costs through predictive maintenance features and asset management tools.

Diverse Industrial Application Spectrum

The application versatility of magnetostrictive level measurement extends across numerous industrial sectors with exceptional results. In chemical processing plants, these sensors provide precise interface detection between immiscible liquids while withstanding aggressive media. Petroleum refineries utilize them for exact tank gauging and overfill prevention systems. Food and beverage manufacturers benefit from their hygienic design and cleaning compatibility, while pharmaceutical applications leverage their validation compliance and documentation capabilities. Water treatment facilities implement these sensors for chemical dosage control and reservoir management, demonstrating the technology's remarkable adaptability across virtually all liquid measurement scenarios.

Economic Advantages and Operational Benefits

Implementing magnetostrictive level control systems generates substantial economic returns through multiple operational advantages. The technology's measurement precision directly translates to reduced product loss, optimized inventory carrying costs, and minimized wastage through exact batch control. Enhanced process reliability decreases production downtime while improving quality consistency through stable operation parameters. Reduced maintenance requirements compared to mechanical alternatives lower total cost of ownership, while the extended service life—often exceeding 15 years in continuous operation—delivers exceptional long-term value and return on investment for industrial operators.

Future Technological Developments

The evolution of magnetostrictive sensing technology continues with emerging innovations that further enhance capability and connectivity. Next-generation sensors incorporate IIoT compatibility with embedded wireless communication protocols, cloud data integration, and advanced prognostic capabilities. Enhanced materials science developments are expanding temperature and pressure operating envelopes while improving corrosion resistance. Miniaturization trends are enabling new application opportunities in compact equipment designs, while improved signal processing algorithms are pushing accuracy boundaries beyond current limitations. These ongoing advancements ensure magnetostrictive technology will remain at the forefront of industrial level measurement for decades to come.

UpgradingYourLevelMeasurementS

UpgradingYourLevelMeasurementS

Why are magnetostrictive level

Why are magnetostrictive level

ComparingMagnetostrictiveandRa

ComparingMagnetostrictiveandRa

MagnetostrictiveLevelSensorfor

MagnetostrictiveLevelSensorfor