MagnetostrictiveLevelTransmitters:Features,Types,andPrices

Understanding Magnetostrictive Level Transmitters

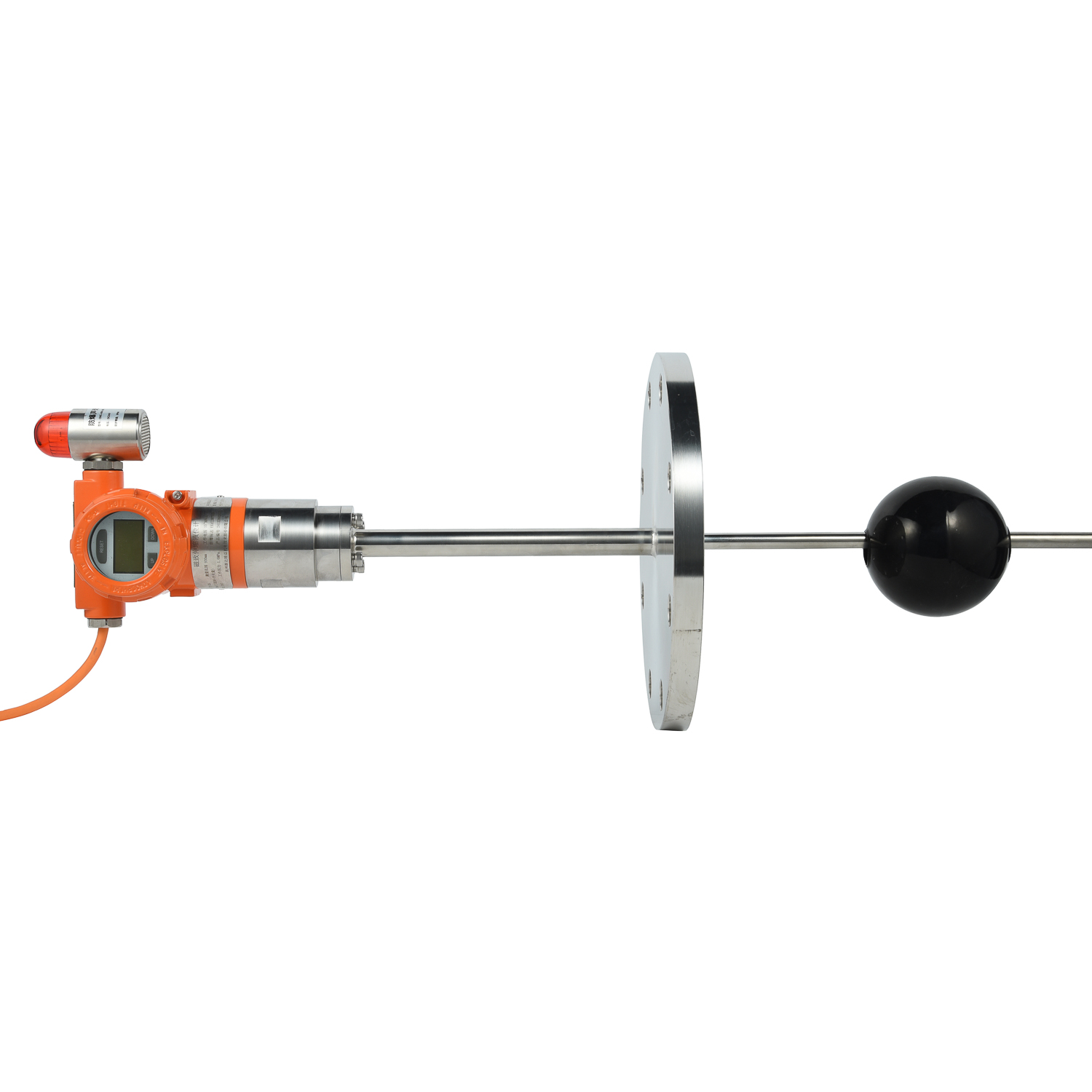

Magnetostrictive level transmitters represent a pinnacle of precision in liquid level measurement technology. These sophisticated devices utilize the magnetostrictive principle to deliver highly accurate, continuous level readings for various industrial applications. At their core, they function by measuring the precise position of a magnetic float that moves with the liquid surface along a magnetostrictive wire. This technology eliminates mechanical linkages and moving parts that often wear out, resulting in exceptional reliability and reduced maintenance needs. Industries ranging from chemical processing to oil and gas rely on these transmitters for their critical operations where level accuracy directly impacts process efficiency and safety. The non-contact measurement principle ensures minimal interference with the process media, making them suitable for everything from corrosive chemicals to high-purity food-grade liquids.

Key Features of Magnetostrictive Level Transmitters

Modern magnetostrictive level transmitters boast an impressive array of features that set them apart from other level measurement technologies. Their most significant advantage lies in their exceptional accuracy, typically reaching ±0.05% of full scale or better, providing reliable data for inventory management and process control. These devices offer excellent resolution, capable of detecting level changes as small as 0.1 millimeters. The robust construction of magnetostrictive transmitters ensures reliable performance even in demanding environments with wide temperature ranges from -196°C to 204°C and pressures up to 340 bar. Many models feature multiple output options including 4-20mA analog signals, HART protocol, Foundation Fieldbus, or PROFIBUS PA for seamless integration with existing control systems. The non-contact sensing element provides virtually infinite resolution and repeatability, while the solid-state design ensures long-term stability with minimal calibration requirements.

Different Types of Magnetostrictive Transmitters

The magnetostrictive level transmitter market offers several configurations to meet specific application requirements. Standard industrial transmitters provide cost-effective solutions for general purpose applications in tanks and vessels. High-pressure models feature reinforced construction for demanding processes in oil and gas production and hydraulic systems. Sanitary designs with polished surfaces and 3A certification meet strict hygiene standards for food, beverage, and pharmaceutical industries. Explosion-proof versions with ATEX and IECEx certifications ensure safe operation in hazardous areas where flammable gases or vapors may be present. Some advanced models incorporate dual-probe technology for simultaneous interface level measurement between two immiscible liquids. Additionally, compact versions are available for limited space applications, while long-stroke models can measure levels in tanks up to 25 meters tall with consistent accuracy throughout the measurement range.

Industrial Applications and Benefits

Magnetostrictive level transmitters find applications across numerous industries due to their versatility and reliability. In the oil and gas sector, they accurately measure crude oil, refined products, and LNG levels in storage tanks and process vessels. Chemical plants utilize them for monitoring aggressive and corrosive liquids where other technologies would fail. The food and beverage industry benefits from sanitary designs for ingredients, finished products, and cleaning solutions. Power generation facilities employ these transmitters for fuel oil, demineralized water, and chemical treatment systems. The primary benefits include reduced maintenance costs due to the non-contact operating principle, improved process efficiency through precise level control, enhanced safety with reliable overfill protection, and comprehensive diagnostic capabilities that enable predictive maintenance. Their digital communication capabilities facilitate integration with asset management systems for centralized monitoring and control.

Price Considerations and Selection Guide

The pricing of magnetostrictive level transmitters varies significantly based on specifications and features, typically ranging from $800 to $3,500 per unit. Basic industrial models with standard accuracy and materials start around $800-$1,200, while high-performance versions with exotic materials for corrosive applications can cost $2,000-$2,800. Specialized designs for extreme conditions or certified for hazardous areas may reach $3,500. When selecting a transmitter, consider the process temperature and pressure ranges, the chemical compatibility of wetted materials, the required measurement range and accuracy, necessary certifications for your industry, and communication protocol requirements. Additional costs may include installation accessories, calibration services, and configuration software. Despite the higher initial investment compared to some technologies, the long-term reliability, minimal maintenance, and operational benefits often result in superior lifetime value and return on investment for critical applications.

UpgradingYourLevelMeasurementS

UpgradingYourLevelMeasurementS

Why are magnetostrictive level

Why are magnetostrictive level

ComparingMagnetostrictiveandRa

ComparingMagnetostrictiveandRa

MagnetostrictiveLevelSensorfor

MagnetostrictiveLevelSensorfor