Why are magnetostrictive level gauges becoming new standards for energy trading?

In the highly regulated world of energy trading, precision and reliability are not just desirable—they are mandatory. The fiscal transfer of valuable liquids like crude oil, refined products, and liquefied natural gas demands measurement technologies that eliminate uncertainty. This relentless pursuit of accuracy is fundamentally reshaping instrumentation standards across the global supply chain. Increasingly, magnetostrictive level gauges are emerging as the definitive solution, displacing older technologies to become the new benchmark for custody transfer operations.

Unmatched Accuracy for Custody Transfer Applications

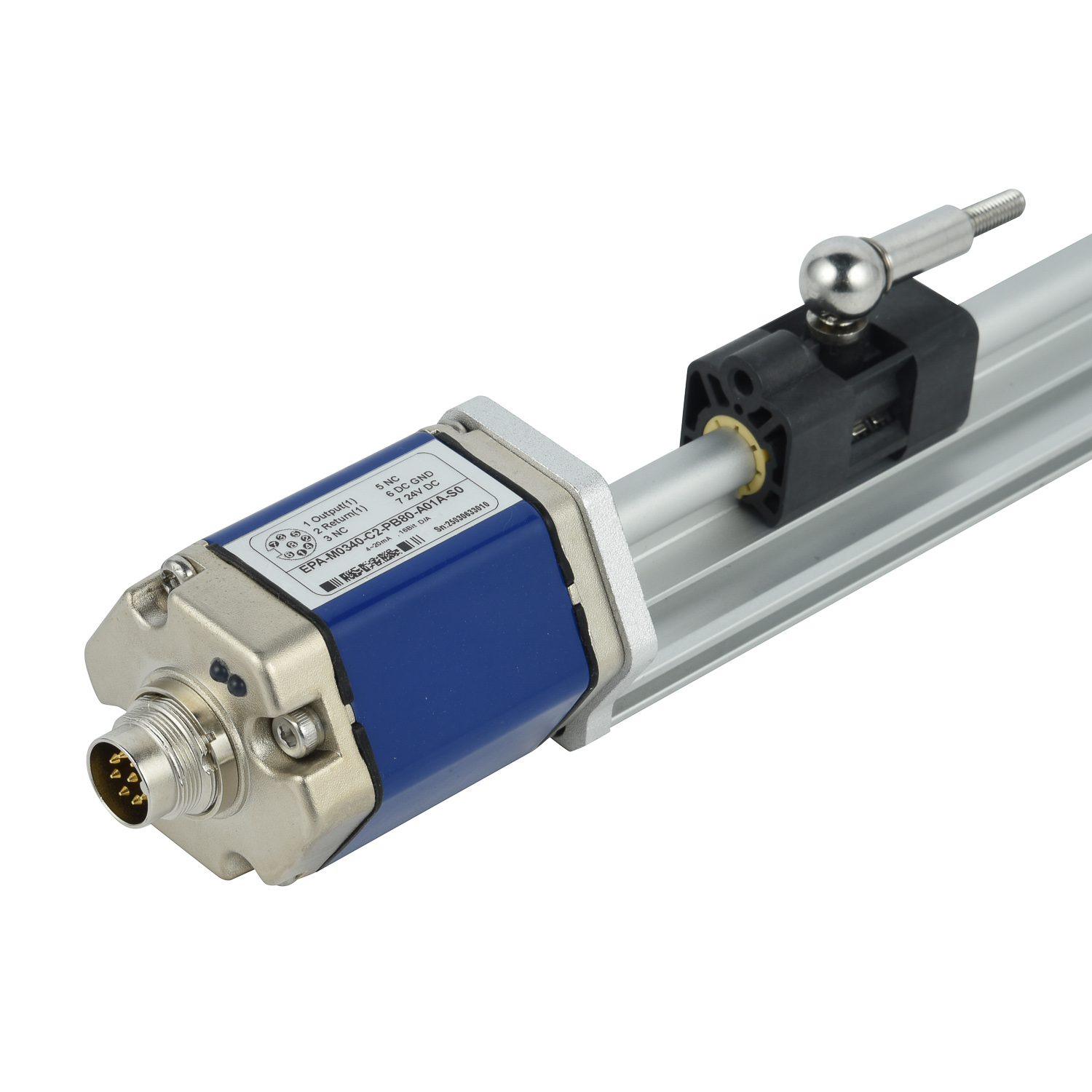

The core of any energy transaction hinges on the precise measurement of volume. Even a minute miscalculation can translate into significant financial losses or disputes between trading partners. Magnetostrictive level gauges operate on a time-based measurement principle, where a torsional stress wave is sent down a magnetostrictive wire. The interaction with a permanent magnet float provides a highly precise position reading. This technology delivers exceptional linearity and repeatability, often with accuracies within ±0.5 mm or better. This level of precision is paramount for custody transfer, where every liter of product must be accounted for, ensuring fairness and trust in every transaction.

Superior Reliability and Reduced Maintenance Costs

Operational downtime and frequent calibration are the enemies of profitability in energy terminals. Traditional mechanical float gauges or servo-powered devices have moving parts that are prone to wear, jamming, and failure. Magnetostrictive transmitters, in contrast, have a non-contact sensing mechanism. The float moves freely along the probe without being mechanically linked to the sensor, drastically reducing mechanical wear. This robust design results in a significantly longer operational lifespan, minimal maintenance requirements, and enhanced system availability, which directly contributes to lower total cost of ownership and uninterrupted operation.

Compliance with Stringent International Standards

The global nature of energy trading necessitates adherence to a complex framework of international standards and regulations. Bodies like the American Petroleum Institute (API) and the International Organization of Legal Metrology (OIML) set rigorous requirements for measurement systems used in custody transfer. Modern magnetostrictive level gauges are engineered specifically to meet and exceed these standards, including API MPMS Chapter 3.1B for tank gauging. Their proven performance and certification capabilities provide the necessary documentation and audit trails for regulatory compliance, making them a safe and approved choice for international trade.

Enhanced Safety in Hazardous Environments

Energy trading facilities often store and handle flammable or explosive materials. Safety is, therefore, a non-negotiable priority. Magnetostrictive level gauges are inherently safe for use in such hazardous areas. They can be designed with intrinsically safe (IS) or explosion-proof (Ex d) enclosures, preventing the instrument from becoming an ignition source. Their reliable and stable performance also reduces the need for personnel to perform manual measurements or frequent maintenance checks near hazardous tanks, thereby enhancing overall site safety.

Seamless Integration with Digital Inventory Systems

The modern energy terminal is a digitally connected ecosystem. Magnetostrictive level transmitters are not just measurement devices; they are intelligent data nodes. They provide a continuous, high-resolution digital output that can be seamlessly integrated into sophisticated Inventory Management Systems (IMS), Distributed Control Systems (DCS), and cloud-based platforms. This enables real-time inventory tracking, automated reporting, and data-driven decision-making, bringing unprecedented transparency and efficiency to the entire energy trading logistics chain.

The convergence of these critical factors—extreme accuracy, robust reliability, regulatory compliance, enhanced safety, and digital readiness—positions magnetostrictive level gauge technology as the clear leader. As the energy trading industry continues to evolve towards greater transparency and efficiency, the adoption of magnetostrictive level gauges is no longer an alternative but is rapidly becoming the new global standard.

UpgradingYourLevelMeasurementS

UpgradingYourLevelMeasurementS

Why are magnetostrictive level

Why are magnetostrictive level

ComparingMagnetostrictiveandRa

ComparingMagnetostrictiveandRa

MagnetostrictiveLevelSensorfor

MagnetostrictiveLevelSensorfor