How to enable wireless network level monitoring with magnetostrictive technology?

Wireless network level monitoring represents a revolutionary approach to industrial infrastructure management, offering unprecedented capabilities for real-time structural health assessment. By integrating magnetostrictive technology with advanced wireless communication systems, industries can now achieve comprehensive monitoring solutions that were previously unimaginable. This innovative combination allows for continuous data collection from remote or difficult-to-access locations, enabling proactive maintenance strategies and significantly reducing operational downtime. The fusion of these technologies marks a significant leap forward in industrial automation and predictive maintenance capabilities.

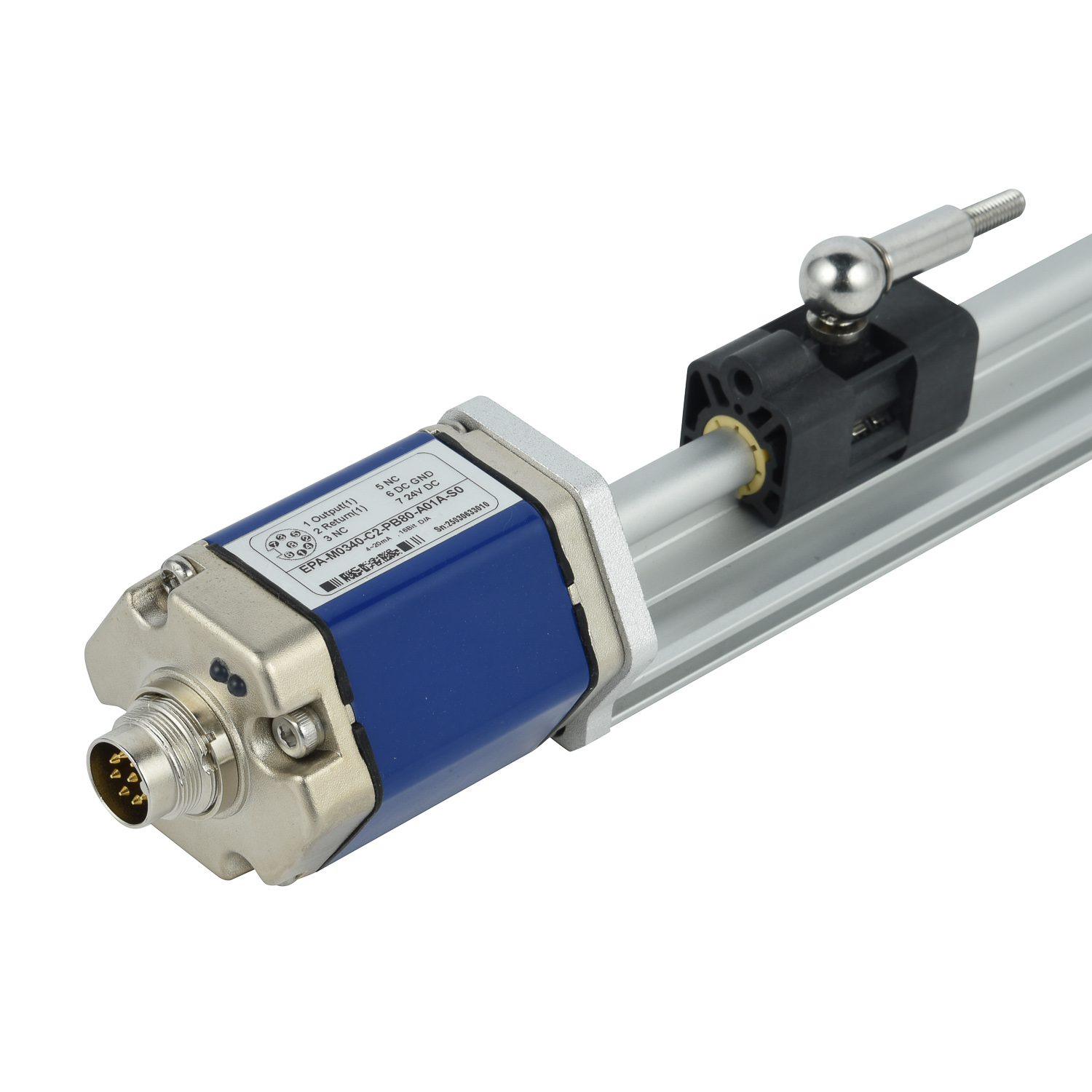

Understanding Magnetostrictive Technology Fundamentals

Magnetostrictive technology operates on the principle that certain materials change their shape or dimensions when subjected to magnetic fields. This unique physical phenomenon forms the basis for highly accurate sensing and monitoring applications. When ferromagnetic materials experience magnetic fields, they undergo minute dimensional changes through the Villari effect, which can be precisely measured and correlated with various physical parameters. These materials typically include nickel, iron-cobalt alloys, and terfenol-D compounds, each offering distinct advantages for specific monitoring applications. The technology's ability to provide direct, absolute position measurement makes it particularly valuable for structural monitoring applications where precision and reliability are paramount.

Implementing Wireless Sensor Networks

The integration of magnetostrictive sensors with wireless networks requires careful planning and strategic implementation. Modern wireless sensor networks typically employ IEEE 802.15.4, Zigbee, or LoRaWAN protocols to ensure reliable data transmission across industrial environments. These networks must be designed with sufficient node density to guarantee continuous coverage while maintaining energy efficiency through sophisticated power management systems. The implementation process involves deploying multiple magnetostrictive sensor nodes that collect structural data and transmit it wirelessly to a central monitoring station. Each node incorporates signal conditioning circuitry, microcontrollers for data processing, and RF transceivers for communication, creating a robust mesh network capable of self-healing and adaptive routing.

System Architecture and Integration

Building an effective wireless monitoring system with magnetostrictive technology demands a comprehensive architectural approach. The system typically comprises three main layers: the sensing layer with magnetostrictive transducers, the network layer handling wireless communication, and the application layer for data analysis and visualization. Integration involves configuring gateways that bridge the wireless sensor network with existing enterprise systems, ensuring seamless data flow from field devices to decision-making platforms. The architecture must support real-time data processing at the edge while maintaining synchronization across all network nodes. Proper integration also requires implementing robust security protocols to protect data integrity and prevent unauthorized access to the monitoring network.

Data Acquisition and Signal Processing

The core of magnetostrictive wireless monitoring lies in its sophisticated data acquisition and processing capabilities. Magnetostrictive sensors generate analog signals that must be converted to digital format through high-resolution analog-to-digital converters. Advanced signal processing algorithms then filter noise, compensate for environmental factors, and extract meaningful information about structural conditions. These systems typically employ digital signal processors running specialized algorithms for feature extraction and anomaly detection. The processed data undergoes compression and packetization before wireless transmission, optimizing bandwidth usage while preserving critical information quality for accurate structural assessment.

Real-time Monitoring Applications

Wireless magnetostrictive monitoring systems excel in real-time industrial applications where continuous structural assessment is crucial. These systems provide immediate detection of structural deformations, stress variations, and potential failure points across various infrastructure elements. In bridge monitoring, for instance, they track deflection patterns and load distribution in real-time. For industrial machinery, they monitor vibration characteristics and component wear. The wireless capability enables monitoring in hazardous environments or rotating equipment where wired solutions are impractical. Real-time data streaming allows operators to implement immediate corrective actions when parameters exceed safe thresholds, significantly enhancing operational safety and equipment reliability.

Power Management Strategies

Effective power management represents a critical aspect of sustainable wireless monitoring systems using magnetostrictive technology. Since these systems often operate in remote locations, implementing efficient energy harvesting and power conservation strategies becomes essential. Common approaches include solar power integration, vibration energy harvesting, and thermal gradient conversion systems. Advanced power management integrated circuits dynamically adjust system operation based on available energy, prioritizing critical monitoring functions during low-power conditions. Sleep scheduling algorithms ensure sensors activate only during designated monitoring intervals, while energy-aware routing protocols optimize network-wide power consumption without compromising data quality or transmission reliability.

Performance Optimization Techniques

Optimizing the performance of wireless magnetostrictive monitoring systems involves multiple technical considerations. Network performance can be enhanced through adaptive frequency hopping to avoid interference, while sensor accuracy improves through temperature compensation and calibration algorithms. System reliability increases with redundant pathway configurations and error correction protocols. Data quality optimization employs sophisticated filtering techniques that distinguish between actual structural changes and environmental noise. Regular system calibration maintains measurement accuracy, while machine learning algorithms continuously improve anomaly detection capabilities based on historical performance data and pattern recognition.

Future Developments and Trends

The future of wireless network level monitoring with magnetostrictive technology points toward increasingly intelligent and autonomous systems. Emerging trends include the integration of artificial intelligence for predictive analytics, development of energy-autonomous sensors using advanced energy harvesting, and implementation of 5G connectivity for enhanced data transmission capabilities. Research focuses on creating multi-functional magnetostrictive sensors capable of measuring multiple parameters simultaneously, while nanotechnology promises smaller, more sensitive transducers. The convergence of magnetostrictive technology with digital twin concepts will enable virtual replication of physical structures, allowing for sophisticated simulation and predictive maintenance modeling that revolutionizes industrial asset management.

UpgradingYourLevelMeasurementS

UpgradingYourLevelMeasurementS

Why are magnetostrictive level

Why are magnetostrictive level

ComparingMagnetostrictiveandRa

ComparingMagnetostrictiveandRa

MagnetostrictiveLevelSensorfor

MagnetostrictiveLevelSensorfor