What does IP65 protection rating mean for magnetostrictive sensors?

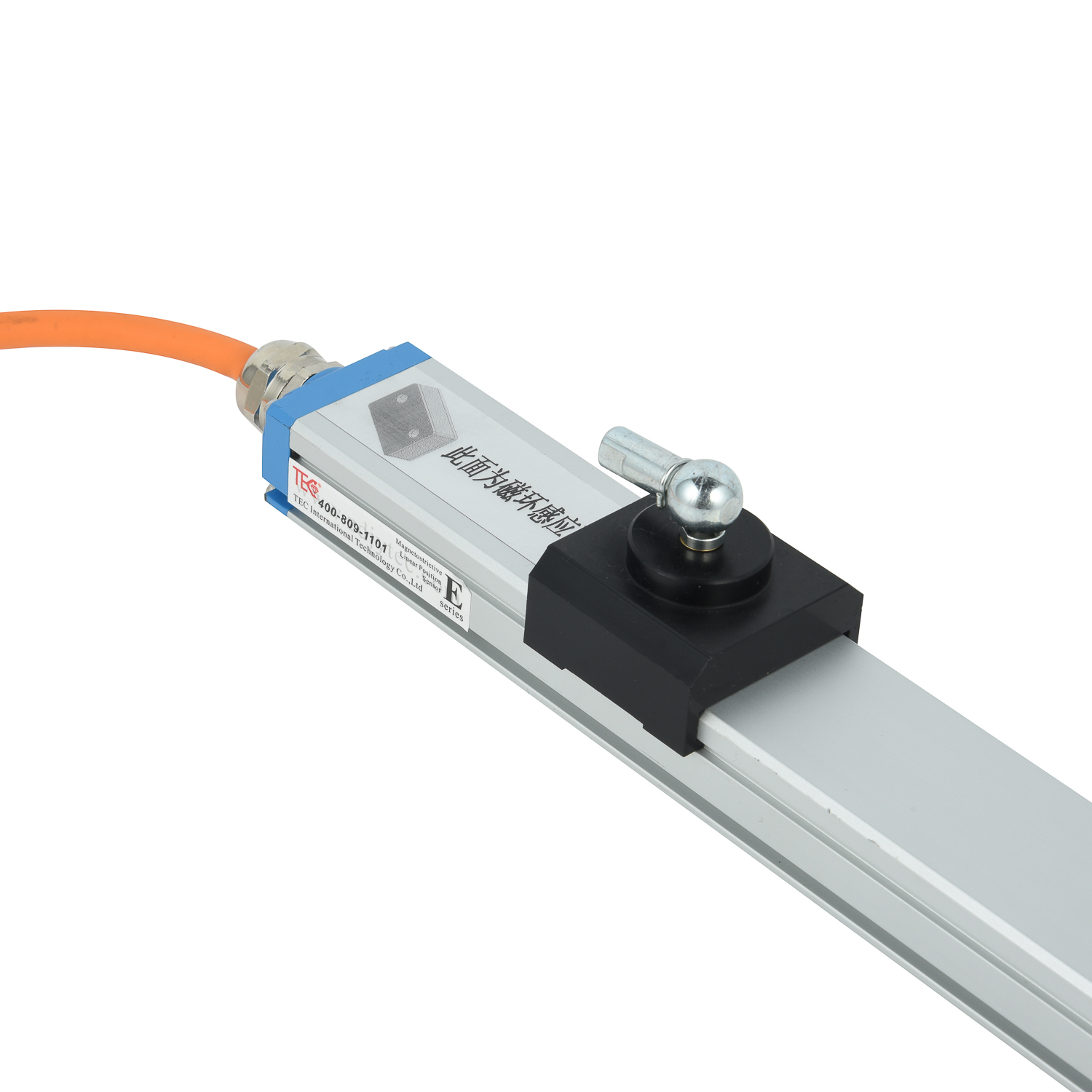

In industrial environments where dust, moisture, and constant exposure to harsh conditions are the norm, equipment durability becomes paramount. For precision instruments like magnetostrictive sensors, which provide accurate linear position measurement in hydraulic cylinders and other machinery, protection against environmental factors is critical to maintaining performance and longevity. This is where the IP65 protection rating enters the picture, serving as a vital benchmark for reliability.

Understanding the IP Code: Breaking Down the Numbers

The IP Code, or Ingress Protection rating, is an international standard defined by IEC 60529 that classifies the degree of protection provided by mechanical casings and electrical enclosures against intrusion, dust, and water. The acronym "IP" is followed by two digits. The first digit indicates the level of protection against solid particles like dust, ranging from 0 (no protection) to 6 (complete protection against dust ingress). The second digit indicates protection against liquids, on a scale from 0 to 9, with higher numbers representing stronger resistance. For magnetostrictive sensors, an IP65 rating is a common and highly valuable specification, assuring users of its robust defensive capabilities.

IP65 Decoded: Dust-Tight and Water-Resistant

Specifically, an IP65 rating guarantees two key levels of protection. The "6" signifies that the sensor is entirely dust-tight. This means no dust can enter the enclosure, which is crucial for preventing internal damage to the sensitive waveguide and electronics that could lead to measurement drift or failure. The "5" denotes protection against low-pressure water jets from any direction. A sensor with this rating can withstand water projected from a nozzle with a 6.3mm diameter, making it resistant to common industrial cleaning processes, incidental spills, and exposure to rain. This combination makes IP65-rated sensors ideal for a vast array of demanding applications.

Why IP65 Matters for Magnetostrictive Sensors

Magnetostrictive sensors operate on the principle of magnetostriction, where a torsion strain wave is generated when two magnetic fields interact. The precise timing of this wave is measured to determine the position of a magnet along the sensor's rod. This internal mechanism is highly sensitive. The presence of conductive dust or moisture inside the enclosure can cause electrical short circuits, corrosion, or interference with the magnetic fields, ultimately compromising the sensor's accuracy and leading to costly downtime. The IP65 rating acts as a shield, ensuring the internal components remain pristine and fully functional, thereby guaranteeing the high accuracy and repeatability these sensors are known for.

Typical Applications for IP65-Rated Magnetostrictive Sensors

The robustness offered by an IP65 rating makes these sensors perfectly suited for challenging environments. You will commonly find them in mobile hydraulics for construction and agricultural machinery, where they are exposed to dirt, mud, and weather. They are indispensable in factory automation, particularly on machinery that requires regular wash-downs, such as in food and beverage processing or pharmaceutical manufacturing. Other common applications include plastic injection molding machines, metal forming presses, and any industrial setting where reliability cannot be compromised by environmental factors.

Selecting and Maintaining Your Sensor

When selecting a magnetostrictive sensor, verifying the IP rating is a critical step in the specification process. While IP65 is excellent for most industrial scenarios, even harsher environments—such as those involving high-pressure, high-temperature wash-downs or temporary submersion—may require a higher rating like IP67 or IP69K. It is also important to note that the rating applies to the sensor's housing and not to the cable entry points or connectors, which must be appropriately specified and installed to maintain the overall integrity of the protection. Regular inspection of the housing and seals is recommended to ensure ongoing performance.

In conclusion, the IP65 rating on a magnetostrictive sensor is far more than just a technical specification on a datasheet; it is a promise of resilience. It provides engineers and plant managers with the confidence that their critical positioning data will remain accurate and reliable, even when the sensors are subjected to the dust and water ever-present in industrial operations. This protection is fundamental to maximizing uptime, reducing maintenance costs, and ensuring the long-term success of automated systems.

UpgradingYourLevelMeasurementS

UpgradingYourLevelMeasurementS

Why are magnetostrictive level

Why are magnetostrictive level

ComparingMagnetostrictiveandRa

ComparingMagnetostrictiveandRa

MagnetostrictiveLevelSensorfor

MagnetostrictiveLevelSensorfor