What is the measuring range of magnetostrictive sensors?

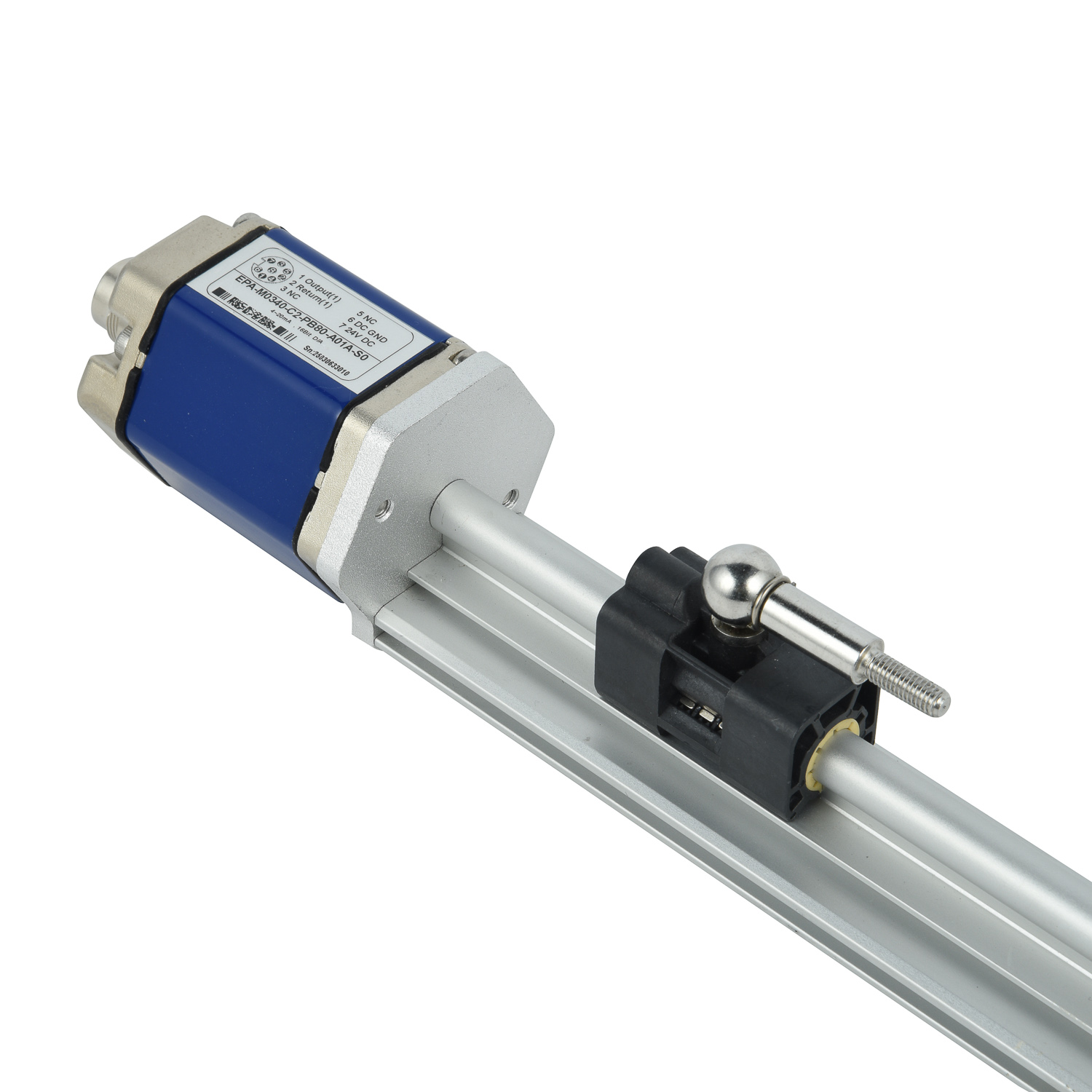

Magnetostrictive sensors represent a sophisticated class of position sensing devices that utilize the magnetostrictive effect to deliver precise linear displacement measurements. These sensors operate by generating an interrogation pulse along a waveguide wire, which interacts with the magnetic field of a position magnet. This interaction produces a torsional strain wave that travels back to the sensor's pickup coil at a constant velocity, enabling highly accurate position determination through precise time-of-flight calculations.

The measuring range of these sensors typically spans from 50 millimeters to over 6000 millimeters, accommodating diverse industrial requirements. This extensive range capability makes them suitable for both compact machinery and large-scale industrial systems where long-range precision measurement is essential. The actual measurable distance depends on the specific sensor design and waveguide length, with manufacturers offering standardized and custom-length options to meet various application needs.

Several critical factors influence the effective measuring range of magnetostrictive sensors. Temperature variations significantly impact performance, as extreme heat or cold can affect the waveguide material properties and signal transmission characteristics. Mechanical installation considerations, including proper alignment and mounting stability, directly affect measurement accuracy across the entire range. The choice of sensing technology—whether using absolute or incremental measurement principles—also determines how position data is acquired and interpreted throughout the measurement span.

In hydraulic cylinder applications, magnetostrictive sensors typically operate within ranges of 100-4000 mm, providing precise piston position feedback. Industrial automation systems often employ sensors with 500-6000 mm ranges for position control in manufacturing processes. The automotive industry frequently utilizes 200-3000 mm sensors for assembly line automation and quality control applications.

When selecting the appropriate measuring range, engineers must consider both the maximum required travel distance and necessary safety margins. It's advisable to choose a sensor whose specified range exceeds the actual application requirement by 10-15% to ensure reliable operation and account for potential over-travel situations. This practice helps maintain measurement integrity while preventing damage to the sensing element.

Modern magnetostrictive sensors incorporate advanced signal processing techniques to maintain accuracy across their entire measuring range. Temperature compensation algorithms automatically adjust measurements based on thermal conditions, while digital filtering eliminates noise interference that could affect long-range signal integrity. These technological advancements ensure consistent performance whether measuring just a few centimeters or several meters of displacement.

The resolution capability within the measuring range typically reaches micrometer levels, with high-end models achieving resolutions up to 1 micron. This exceptional precision remains consistent throughout the entire measurement span, unlike some sensing technologies where accuracy diminishes over longer distances. The non-contact nature of the measurement principle ensures virtually wear-free operation and maintains calibration stability across the sensor's operational lifespan.

As industries continue to demand higher precision and longer measurement capabilities, magnetostrictive sensor technology evolves to meet these challenges. Ongoing research focuses on extending measuring ranges while improving accuracy and reliability, particularly in extreme environmental conditions. These advancements continue to expand the application possibilities for magnetostrictive sensing technology across various industrial sectors.

UpgradingYourLevelMeasurementS

UpgradingYourLevelMeasurementS

Why are magnetostrictive level

Why are magnetostrictive level

ComparingMagnetostrictiveandRa

ComparingMagnetostrictiveandRa

MagnetostrictiveLevelSensorfor

MagnetostrictiveLevelSensorfor