Can magnetostrictive sensors operate in high-temperature environments?

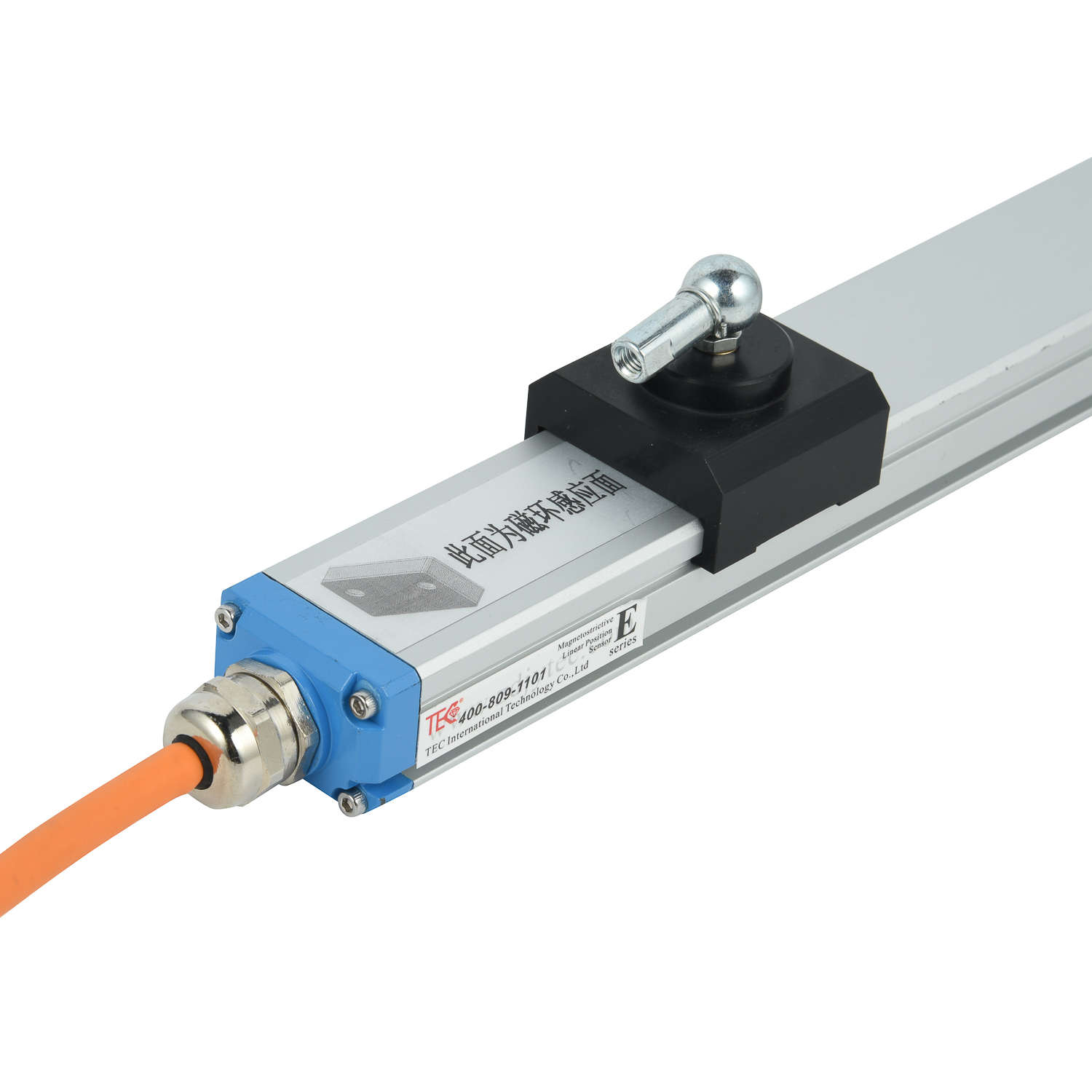

Magnetostrictive sensors have emerged as critical components in modern industrial applications, particularly where precise position and liquid level measurements are required under challenging conditions. These sophisticated devices operate based on the magnetostriction principle, where ferromagnetic materials change their shape or dimensions when subjected to magnetic fields. This unique physical phenomenon enables highly accurate and reliable measurements even in demanding operational environments. The fundamental working mechanism involves generating a magnetic pulse that travels along a waveguide, interacting with a permanent magnet to produce torsional stress waves that are measured with exceptional precision.

When evaluating high-temperature performance capabilities, modern magnetostrictive sensors demonstrate remarkable resilience through advanced engineering solutions. Contemporary models can reliably operate in environments reaching temperatures up to 1000°C when equipped with specialized thermal protection systems. This exceptional temperature tolerance is achieved through multiple technological innovations including high-temperature-resistant waveguide materials, advanced thermal barrier coatings, and sophisticated cooling mechanisms that maintain internal components within safe operating ranges. The sensor's ability to maintain accuracy under thermal stress makes it invaluable for critical applications where temperature fluctuations would compromise conventional sensing technologies.

The material composition plays a pivotal role in determining thermal performance characteristics. Manufacturers utilize specialized alloys including iron-cobalt-vanadium compounds and nickel-iron formulations that maintain their magnetostrictive properties at elevated temperatures. These advanced materials are engineered to minimize thermal expansion effects while preserving magnetic permeability characteristics. Additionally, waveguide tubes are often constructed from high-temperature stainless steel or Inconel alloys that resist oxidation and maintain structural integrity. The careful selection of these materials ensures consistent performance while preventing signal degradation that could compromise measurement accuracy.

Industrial applications for high-temperature magnetostrictive sensors span numerous sectors including metallurgical processing, aerospace propulsion systems, and power generation facilities. In steel manufacturing, these sensors provide precise level measurements in molten metal containers operating above 800°C. Aerospace implementations include fuel level monitoring in jet engines and hydraulic system measurements where ambient temperatures regularly exceed 500°C. Power generation facilities utilize these sensors for turbine control and boiler level measurements where reliability under thermal stress is paramount for operational safety and efficiency.

Several critical design considerations enable successful high-temperature operation. Effective thermal isolation between the sensing element and electronics compartment prevents heat transfer to sensitive components. Advanced cooling systems utilizing air or liquid circulation maintain internal temperatures within acceptable limits. Specialized signal processing algorithms compensate for temperature-induced variations in wave propagation speed, ensuring consistent measurement accuracy. Additionally, manufacturers incorporate thermal expansion compensation mechanisms that automatically adjust readings based on real-time temperature data, maintaining precision across the entire operational range.

Despite these advanced features, performance limitations do exist at extreme temperature thresholds. Signal-to-noise ratios may decrease significantly above 900°C, requiring enhanced signal processing capabilities. Material stress and potential deformation can occur with prolonged exposure to upper temperature limits, necessitating regular maintenance intervals. Manufacturers typically specify maximum continuous operating temperatures and recommend derating factors for applications approaching these limits. Understanding these constraints is essential for proper sensor selection and implementation in critical high-temperature processes.

Future developments focus on enhancing high-temperature capabilities through nanotechnology and advanced material science. Research initiatives explore carbon nanotube composites and ceramic matrix materials that could extend operational limits beyond current thresholds. Wireless temperature compensation systems and self-cooling mechanisms using thermoelectric principles represent promising avenues for innovation. These advancements aim to push operational boundaries while improving reliability and reducing maintenance requirements in the most demanding industrial environments.

Comparative analysis with alternative sensing technologies reveals distinct advantages in high-temperature scenarios. Unlike capacitive sensors that suffer from dielectric breakdown or ultrasonic sensors affected by air density changes, magnetostrictive sensors maintain superior accuracy under thermal stress. Their non-contact measurement principle eliminates mechanical wear issues common in resistive sensors at elevated temperatures. While fiber optic sensors offer similar high-temperature capabilities, magnetostrictive technology provides better cost-effectiveness for most industrial applications requiring precise measurements under thermal duress.

Implementation best practices include thorough thermal profiling of the installation environment and proper selection of mounting configurations that minimize heat transfer. Regular calibration against known references at operating temperatures ensures maintained accuracy. Environmental protection measures including heat shields and cooling jackets significantly extend service life. Monitoring thermal cycling patterns and implementing predictive maintenance schedules based on temperature exposure history help prevent unexpected failures and ensure continuous operational reliability.

The verification and validation process for high-temperature performance involves rigorous testing protocols including thermal shock tests, prolonged exposure trials, and accuracy measurements across the entire temperature spectrum. Manufacturers subject sensors to multiple thermal cycles while monitoring performance parameters to guarantee reliability. Third-party certifications from organizations like ATEX and IEC provide additional assurance of performance claims, giving engineers confidence when specifying these sensors for critical high-temperature applications.

UpgradingYourLevelMeasurementS

UpgradingYourLevelMeasurementS

Why are magnetostrictive level

Why are magnetostrictive level

ComparingMagnetostrictiveandRa

ComparingMagnetostrictiveandRa

MagnetostrictiveLevelSensorfor

MagnetostrictiveLevelSensorfor