Top5BenefitsofUsingMagnetostrictiveDisplacementSensorsinIndustrialAutomation

In the demanding world of industrial automation, precision and reliability are non-negotiable. Magnetostrictive displacement sensors have emerged as a superior solution for precise position and velocity feedback in a wide array of applications. These sensors offer a unique combination of performance characteristics that make them indispensable in modern manufacturing and processing environments. From robotic arms to hydraulic presses, their ability to deliver accurate data under tough conditions is transforming operational efficiency. This article delves into the five key advantages that make this technology a cornerstone of industrial innovation.

1. Unmatched Accuracy and High Resolution for Precision Tasks

The primary advantage of magnetostrictive sensors lies in their exceptional accuracy and high resolution. Unlike other sensing technologies, they provide non-contact, absolute position measurement with remarkable precision, often down to micrometers. This is critical for applications requiring exact movement control, such as in CNC machining, injection molding, or precision assembly lines. The technology ensures that every movement is measured and controlled with the highest degree of certainty, minimizing errors and enhancing the quality of the final product.

2. Robust Durability and Reliability in Harsh Environments

Industrial settings are notoriously harsh, with exposure to extreme temperatures, vibrations, moisture, and corrosive chemicals. Magnetostrictive sensors are engineered to thrive in these conditions. Housed in sturdy, sealed stainless steel tubes, they are inherently resistant to shock, vibration, and common industrial contaminants. This rugged construction translates to exceptional long-term reliability and reduced downtime, as the sensors continue to perform accurately without faltering, even in the most challenging environments like steel mills or offshore platforms.

3. Simplified Installation and Reduced Maintenance Requirements

The design simplicity of magnetostrictive sensors significantly eases the installation process. Their non-contact operation means there is no mechanical wear between the sensing element and the position magnet, eliminating a primary source of failure. This inherent characteristic drastically reduces the need for frequent calibration or routine maintenance. Once installed, they provide a set-and-forget solution, lowering the total cost of ownership and freeing up technical staff to focus on other critical tasks.

4. Versatile Integration into Diverse Automated Systems

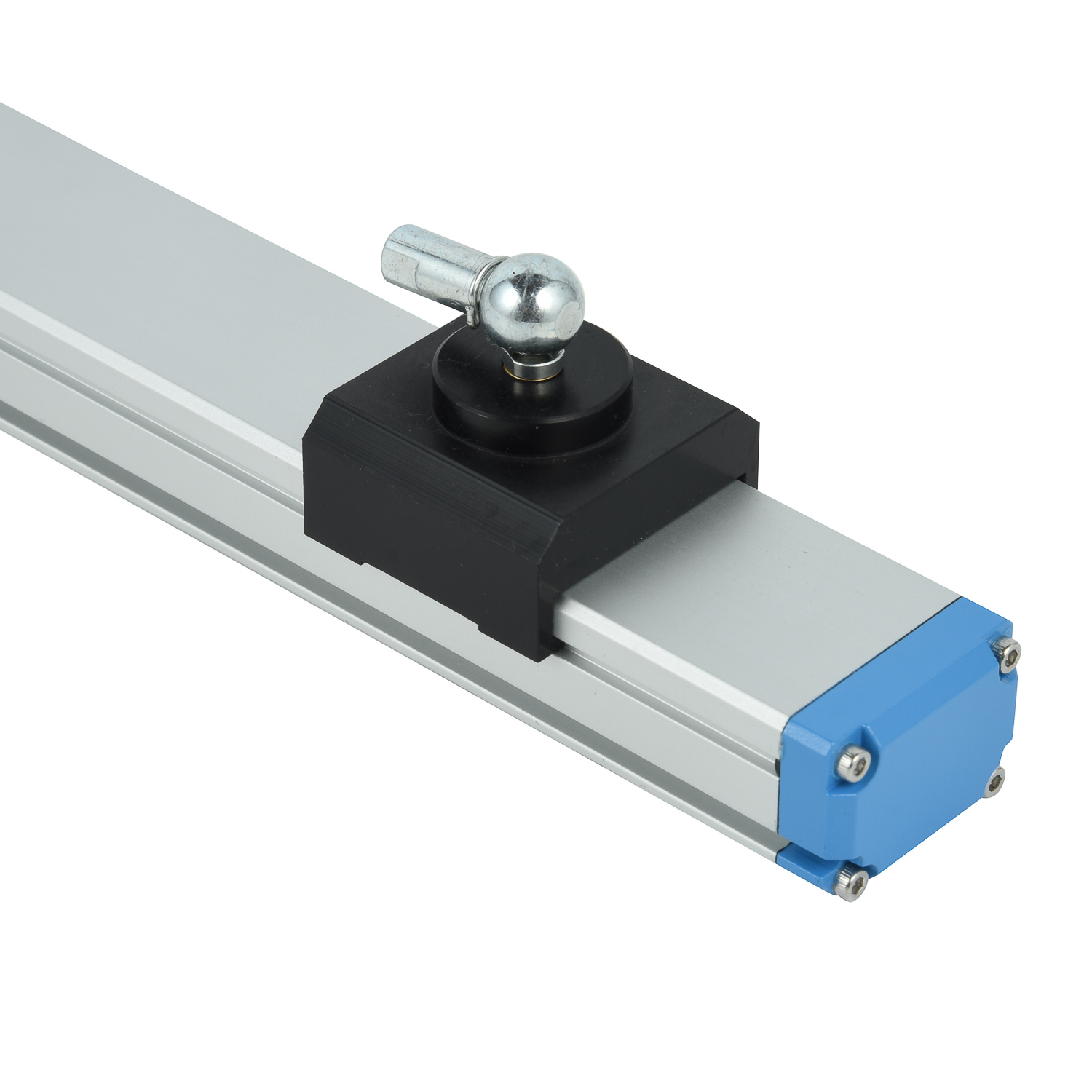

A significant benefit is their remarkable versatility. Magnetostrictive displacement sensors can be seamlessly integrated into a vast range of systems, from monitoring the stroke of hydraulic and pneumatic cylinders to controlling the position of automated guided vehicles (AGVs). Their ability to provide accurate feedback in both linear and rotary applications makes them a go-to component for system designers looking for a unified and reliable sensing solution across multiple platforms and machinery.

5. Enhanced System Performance and Operational Efficiency

Ultimately, the integration of magnetostrictive sensors leads to a direct improvement in overall system performance and efficiency. The precise data they deliver enables tighter control over machinery, optimizing cycle times, improving repeatability, and ensuring consistent product quality. This optimization minimizes waste and energy consumption, leading to higher throughput and lower operational costs. By providing reliable feedback, these sensors are key enablers of smarter, more efficient, and more profitable automated operations.

UpgradingYourLevelMeasurementS

UpgradingYourLevelMeasurementS

Why are magnetostrictive level

Why are magnetostrictive level

ComparingMagnetostrictiveandRa

ComparingMagnetostrictiveandRa

MagnetostrictiveLevelSensorfor

MagnetostrictiveLevelSensorfor